The Power of Modular Automation Systems

06/11/2023 | Share:

Introduction: Embracing Efficiency through Modular Automation

In the fast-paced world of logistics, where adaptability and efficiency reign, the integration of automation systems has become indispensable. Among the myriad advancements, Modular Automation Systems have emerged as a game-changer, offering unparalleled flexibility and scalability to meet the evolving needs of modern businesses. In this blog post, we’ll delve into the transformative power of Modular Automation Systems, exploring their key attributes and the impact they are making on logistics operations worldwide.

1. Understanding Modular Automation Systems

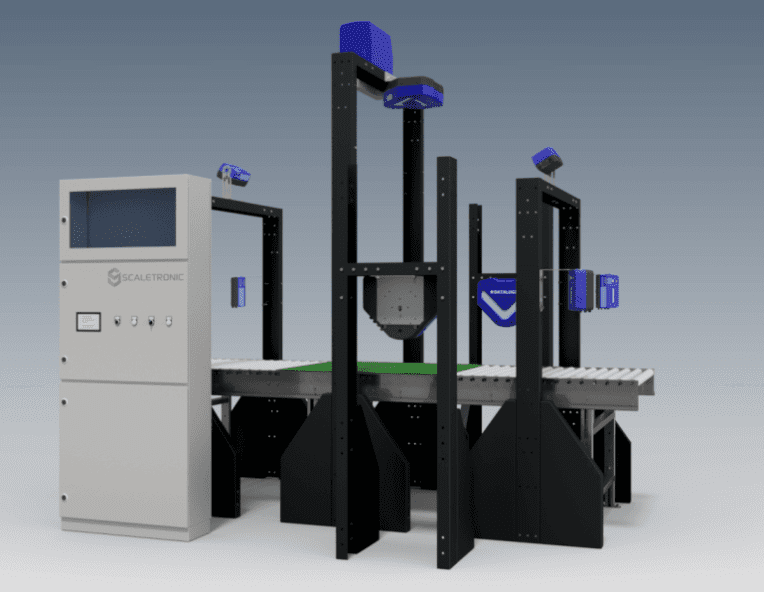

- Adaptable Building Blocks: Modular Automation Systems are composed of interchangeable modules or components that can be easily configured and reconfigured according to specific requirements.

- Seamless Integration: These systems seamlessly integrate various automation technologies such as sorting, scanning, weighing, and conveying into a cohesive and synchronized workflow.

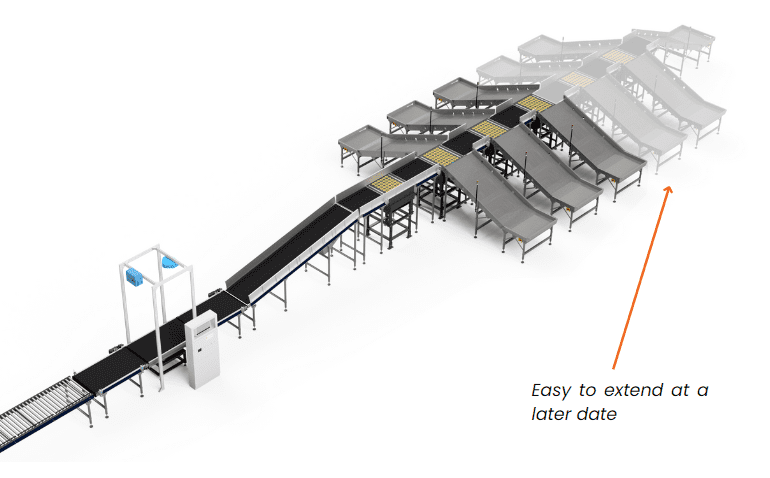

- Scalability: Modular systems can be scaled up or down effortlessly, allowing businesses to adjust their automation infrastructure in response to fluctuating demand or operational expansions.

2. Flexibility Redefined

- Customization Capabilities: Modular systems offer a high degree of customization, enabling businesses to tailor their automation setups precisely to their unique needs.

- Quick Reconfiguration: Rapid reconfiguration of modules facilitates swift adaptation to changing product profiles, ensuring minimal downtime during transitions.

- Future-Proofing: The inherent flexibility of modular systems future-proofs logistics operations, enabling businesses to integrate new technologies without overhauling the entire system.

3. Advantages of Modular Automation Systems

- Optimized Workflow: Modular systems optimize workflow by streamlining processes, reducing bottlenecks, and minimizing human intervention, leading to enhanced productivity.

- Error Reduction: Automation minimizes human errors in tasks such as sorting, reducing the likelihood of mislabeled or misplaced items, and enhancing order accuracy.

- Cost Efficiency: By allowing businesses to scale their automation infrastructure incrementally, modular systems optimize costs by preventing unnecessary investments in overly complex setups.

4. Real-World Applications

- E-commerce Fulfillment: Modular systems empower e-commerce businesses to handle diverse product ranges efficiently, ensuring swift order processing and timely deliveries.

- Parcel Sorting: In logistics hubs, these systems revolutionize parcel sorting, enabling the seamless categorization and routing of packages based on size, weight, or destination.

- Distribution Centers: Distribution centers leverage modular automation to manage inventory, speed up order fulfillment, and enhance supply chain transparency.

5. Conclusion: Embracing the Future of Logistics

In an era where agility and efficiency are paramount, Modular Automation Systems stand as a beacon of innovation in the logistics landscape. Their ability to adapt, scale, and optimize operations not only elevates efficiency but also fosters a competitive edge for businesses.

As we step into the future of logistics, embracing the power of modular automation is not just a choice but a strategic imperative, propelling logistics and warehousing businesses into the future.