Efficiency and Accuracy with Check Weigh Cube (CWC)

29/06/2023 | Share:

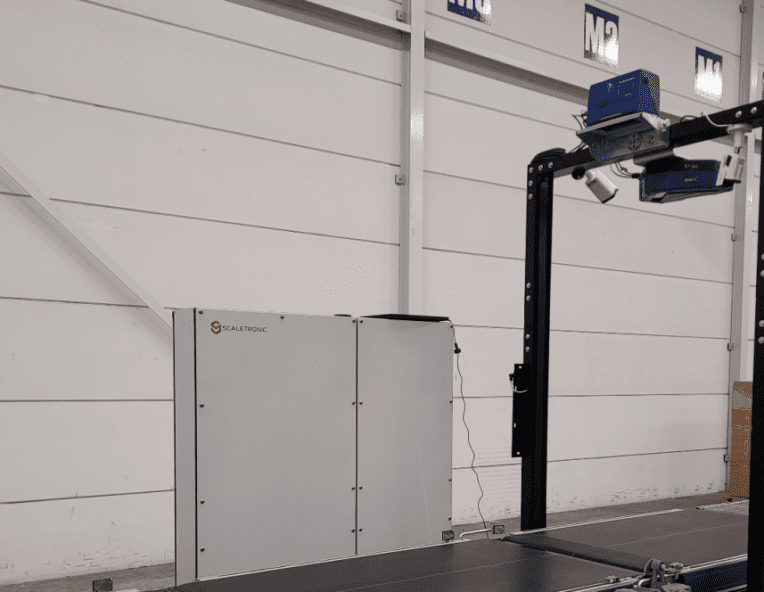

In the fast-paced world of logistics and shipping, accurate measurement of packages is crucial for cost optimization, compliance, and customer satisfaction. Enter Check Weigh Cube (CWC), also known as Dimension Weigh Scan (DWS) – an innovative solution that revolutionizes the way businesses handle dimensioning and weighing processes. In this blog post, we will explore the benefits of CWC/DWS and how it can streamline operations, improve efficiency, and ensure accurate measurements.

Streamlined Dimensioning and Weighing:

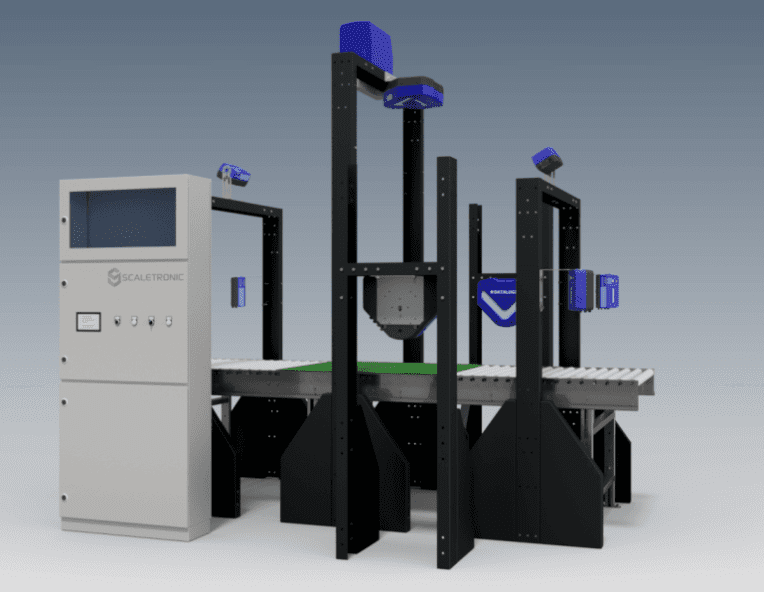

CWC/DWS eliminates the need for separate dimensioning and weighing equipment, combining these two functions into a single integrated system. With a user-friendly interface and intuitive operation, it simplifies the measurement process, saving time and effort. By seamlessly capturing weight and dimensions, businesses can accurately calculate shipping costs, optimize space utilization, and prevent under or overcharging.

Accurate and Reliable Measurements:

Precision is the cornerstone of successful logistics operations, and CWC/DWS delivers just that. With advanced sensors and sophisticated algorithms, it ensures highly accurate and reliable measurements, even for irregularly shaped packages. By eliminating manual errors and guesswork, businesses can maintain consistency, avoid revenue losses, and build trust with customers through precise invoicing and transparent pricing.

Compliance and Cost Optimization:

In the logistics industry, compliance with weight and size restrictions is crucial to avoid penalties and delays. CWC/DWS provides real-time data on package dimensions and weights, enabling businesses to adhere to industry regulations and carrier requirements. By ensuring compliance, businesses can prevent unexpected charges, minimize rework, and optimize costs through accurate invoicing and efficient space utilization.

Enhanced Efficiency and Productivity:

Traditional dimensioning and weighing processes can be time-consuming and labor-intensive. CWC/DWS automates and streamlines these tasks, significantly improving efficiency and productivity. Its fast scanning and instant measurement capabilities enable swift handling of large volumes of packages. With reduced manual intervention and streamlined operations, businesses can allocate resources more efficiently, minimize bottlenecks, and handle higher order volumes with ease.

Seamless Integration and Scalability:

CWC/DWS is designed for seamless integration into existing logistics setups. With flexible integration options, such as API or FTP communication, it can connect with various Warehouse Management Systems (WMS) or Enterprise Resource Planning (ERP) systems. Additionally, its modular design allows for scalability, adapting to evolving business needs and accommodating future growth seamlessly.

Check Weigh Cube (CWC) is a game-changer in the world of logistics. By combining dimensioning and weighing functions into one integrated system, CWC brings efficiency, accuracy, and compliance to package measurement processes. With its streamlined operations, precise measurements, and seamless integration capabilities, businesses can optimize costs, enhance productivity, and deliver exceptional customer experiences. Embrace the power of CWC, and unlock a new era of efficiency and accuracy in your logistics operations.

Remember, when it comes to precise measurements, Check Weigh Cube (CWC) automation is what you need!