Scaling Your Sorting Operations: When and How to Expand

26/09/2024 | Share:

As your logistics business grows, so does the demand for efficient sorting operations. Scaling your sorting system at the right time can significantly enhance your capacity, reduce errors, and improve overall productivity. However, knowing when and how to expand requires careful planning and the right solutions. Here’s a straightforward guide to help you recognize the right time to scale and how Scaletronic’s modular solutions can support your growth.

Recognizing the Right Time to Scale

- Increased Volume of Shipments When your daily shipment volumes consistently exceed your current sorting capacity, it’s a clear indicator that it’s time to scale. For instance, if your facility handles 10,000 packages a day and this number is steadily increasing by 15% each month, your existing system may soon become a bottleneck.

- Rising Error Rates Higher volumes often lead to increased errors in sorting. If you notice that misrouted packages are becoming more frequent, it’s a sign that your system is struggling to keep up. Error rates above 1% can significantly impact customer satisfaction and operational costs.

- Extended Processing Times Longer sorting times can delay deliveries and reduce throughput. If your average processing time per package starts to creep up, it may indicate that your current system cannot handle the increased workload efficiently.

- Employee Overload When your staff is consistently working overtime to manage sorting tasks, it can lead to burnout and higher turnover rates. Efficient automation solutions can alleviate this pressure by handling repetitive tasks, allowing employees to focus on more critical activities.

- Business Growth Plans If you have plans to expand into new markets or increase your service offerings, scaling your sorting operations in advance ensures that you can meet future demands without compromising on quality or speed.

How to Scale Your Sorting Operations

- Assess Your Current System Begin by evaluating the performance of your existing sorting system. Identify areas where delays, errors, or inefficiencies occur. Use this data to determine the specific requirements for scaling, such as increased throughput or enhanced accuracy.

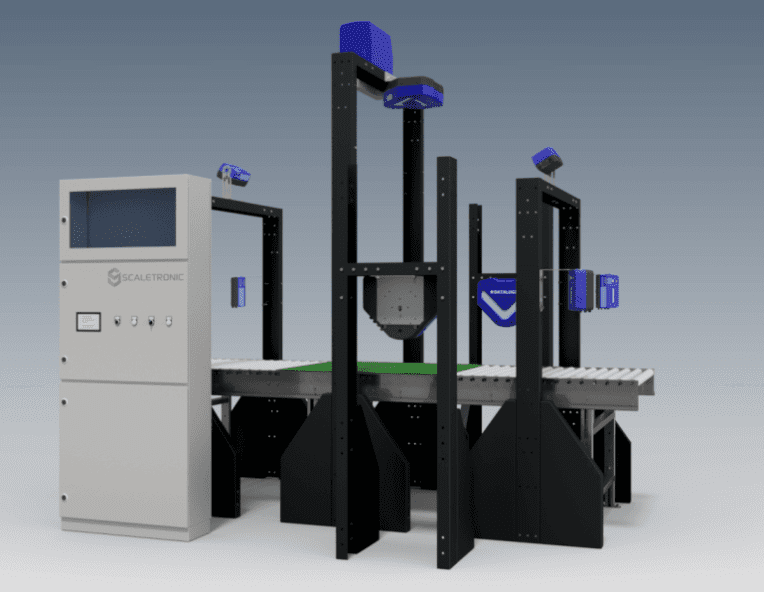

- Invest in Modular Solutions Scaletronic offers modular sorting systems that can be easily expanded as your business grows. Unlike fixed systems, modular solutions allow you to add or upgrade components without overhauling your entire setup. This flexibility ensures that you can scale incrementally based on your needs and budget.

- Integrate Advanced Data Capture Accurate data capture is crucial for efficient sorting. Scaletronic’s scalable solutions come with advanced data capture technologies that provide real-time insights into your operations. This data helps you make informed decisions, optimize workflows, and reduce errors.

- Enhance Automation with Wheel Sorter Technology Our Wheel Sorter technology is designed to adapt to growing demands. It offers scalable, modular sortation that can handle varying package sizes and volumes. This technology ensures that your sorting operations remain efficient and reliable, even as your business expands.

- Focus on Training and Support Scaling your operations isn’t just about adding new equipment; it’s also about ensuring your team can effectively manage the expanded system. Scaletronic provides comprehensive training and ongoing support to help your staff adapt to new technologies and maximize their efficiency.

Real-Life Example

Consider a mid-sized courier company that started handling 8,000 packages daily. As their business grew, they experienced a 20% monthly increase in shipment volumes. Their existing sorting process began to show signs of strain, with error rates rising from 1% to 4% and processing times increasing by 25%.

By partnering with Scaletronic, they implemented a modular sorting solution that allowed them to expand their capacity in phases. The introduction of Wheel Sorter technology reduced their sort error rates to below 0.1% and improved processing times by 30%. With the new scalable system in place, the company was able to handle a peak volume of 20,000 packages per day without compromising on efficiency or customer satisfaction.

Conclusion

Scaling your sorting operations is essential for sustaining growth and maintaining high service standards. By recognizing the right time to expand and implementing scalable, modular solutions like those offered by Scaletronic, you can ensure that your logistics operations remain efficient, accurate, and capable of meeting increasing demands. Invest in the right technology today to support your business’s growth tomorrow.

For more information on how Scaletronic can help scale your sorting operations, contact us today and let our experts guide you towards a more efficient and scalable future.