What is a Cross Belt Sorter?

05/10/2023 | Share:

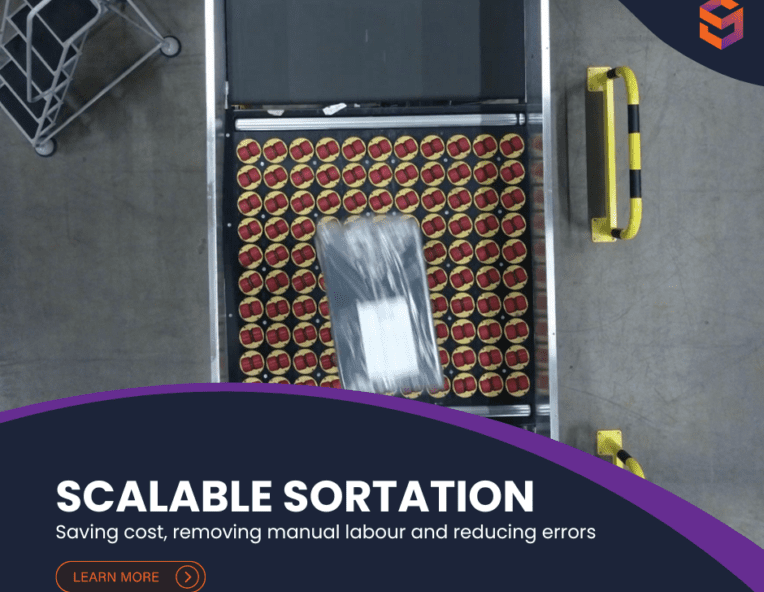

A cross-belt sorter is a type of automated sorting system used in logistics, distribution centers, and warehouses to efficiently sort a wide range of items, such as packages, parcels, and items of various sizes and shapes. The name “cross-belt” refers to the technology’s use of a series of small belts that are mounted on individual carriers or carts.

Here’s how a cross-belt sorter works:

- Induction: Items to be sorted are introduced onto the sorter from an upstream conveyor or source. This can be done manually or automatically through scanning or barcode recognition systems.

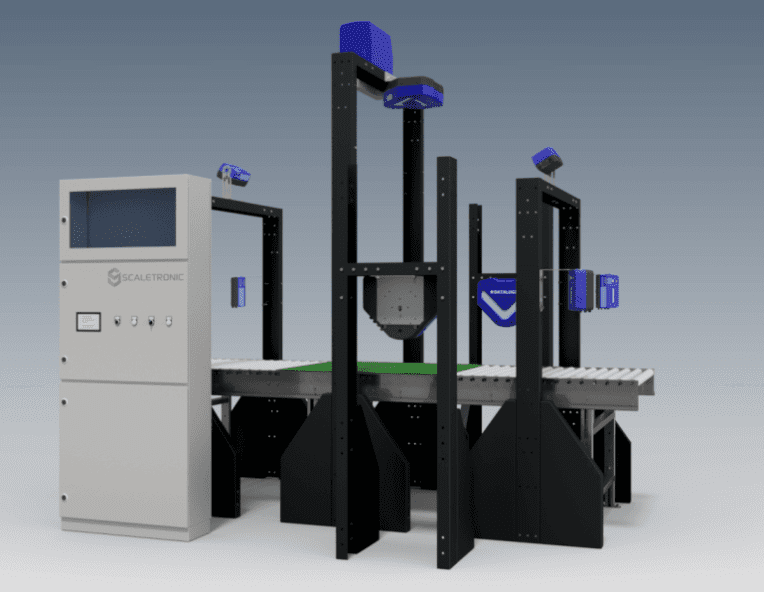

- Carriers with Belts: The cross-belt sorter consists of a conveyor system with individual carriers or carts. Each carrier has a small belt mounted on it. These belts can move both left/right and forwards.

- Sorting Action: As items move along the main conveyor, the cross-belt carriers are strategically positioned to divert items onto chutes or conveyors leading to their designated destinations.

- Belt Movement: When an item needs to be diverted, the small belt on the carrier rotates or moves to position the item over the appropriate chute or conveyor. The item is then gently released onto the chute.

- Destination Chutes: Each chute corresponds to a specific destination, such as a shipping lane, customer order, or storage area. Items are sorted based on predetermined criteria and are directed to the corresponding chute.

- Continuous Operation: Cross-belt sorters operate continuously, with carriers and belts continually repositioning to sort items efficiently. New items are introduced onto the conveyor as others are sorted.

Key Features and Benefits of Cross-Belt Sorters:

- High Throughput: Cross-belt sorters are known for their high sorting capacity, making them suitable for distribution centers and warehouses with large sorting volumes.

- Versatility: They can handle a wide variety of items, including small packages, irregularly shaped items, and fragile products, making them versatile for different industries.

- Gentle Handling: The gentle sorting process minimizes the risk of damage to items, which is crucial for handling delicate or valuable goods.

- Accuracy: Cross-belt sorters are precise in diverting items to the correct chutes, reducing sorting errors and improving order accuracy.

- Modular Design: They often have a modular design, making them adaptable and expandable to accommodate changing sorting needs.

- Real-time Tracking: Integration with tracking and control systems allows for real-time monitoring and reporting of sorting processes.

- Space Efficiency: Cross-belt sorters can be configured to save space, making them suitable for facilities with limited square footage.

Overall, cross-belt sorters are a popular choice for high-speed and high-capacity sorting operations, and their flexibility and accuracy make them valuable tools in the logistics and distribution industry.

Get in touch with the Scaletronic team to learn more about cross belt sortation systems