Parcel Sorting Automation Can’t Wait

The ideal solution to handle increasing volumes, will be to automate processes, reduce manual intervention to prevent errors from occurring, and implement a long-term answer to this issue. Parcel automation is therefore essential to consider.

By Scaletronic | 26/09/2022 | Share:

Shoppers have embraced e-commerce, and, for retailers, it has been a boon.

The volume of products that people are buying online is skyrocketing.

For shippers, the rapid rise in e-commerce has been good and bad. While increased shipping volumes mean greater revenues, many shippers have been caught out by the dynamic changes in the marketplace, leading to missteps and missed opportunities.

Not only are companies handling more parcels, they are also doing so with customers increasingly expecting faster shipments.

To address these issues of speed and volume, many shippers have turned to a solution they’ve leaned on in the past: adding staff for parcel sorting. But that simply may not be enough anymore. It only increases the opportunity for error and is far from a long-term answer. The better solution is automation.

WHY AUTOMATION?

Automation in parcel sorting can bring four distinct advantages that not only help shippers process an increasing load of parcels more quickly, but can also provide company executives data they need to improve efficiencies and lower costs.

Accuracy.

Hand sorting can introduce errors into the sorting process. That means packages may get misrouted, and those kinds of mistakes affect delivery times and customer satisfaction.

Better traceability.

The benefit here is twofold. First, customers want to know where their packages are in the shipping process. Second, knowing when a package gets from Point A to Point B gives shippers data about operational efficiency.

Improved operations.

Shippers can use the data collected from making packages traceable in conjunction with analytics software to smooth an operation’s rough edges. With the ability to know where packages are and when, shippers can precisely plan equipment use and staffing.

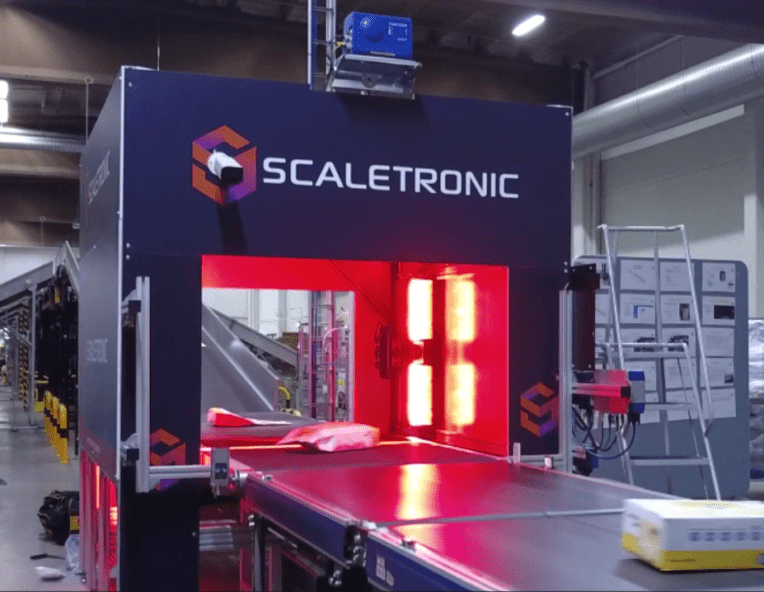

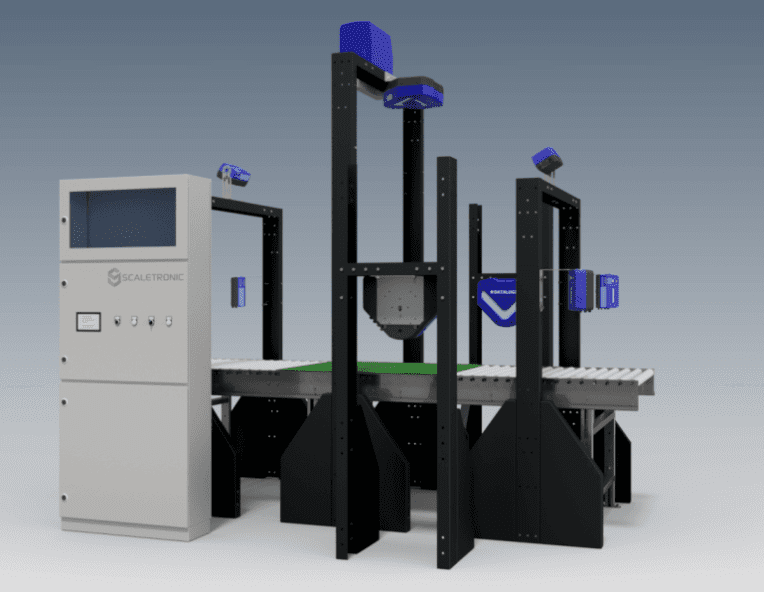

Shift to a distributed sorting model.

The traditional hub-and-spoke model can be inefficient. It can add both cost and delivery time to a process that needs to become faster if it’s going to handle e-commerce requirements. By installing smaller and faster equipment at all regional sites, companies can shift to a distributed sorting model.

WHY NOW?

If shippers are going to have a conversation about automation—and, clearly, they should—now is the time to do it. It’s time for frank talk and real analysis of your holiday season performance. What do you handle well? Where are the difficulties? What could you improve?

Having those conversations and embracing the need for automation can lead to fewer misrouted packages, disappointed customers, and frustrated clients.

WHAT EMBRACING AUTOMATION LOOKS LIKE

Transitioning to automation doesn’t necessarily mean a rip and replace of all existing equipment. You can approach it strategically.

As companies look to shift away from hub-and-spoke models, one good place to start can be to automate parcel sorting at local and regional distribution centers. In the past, the volumes at such centers may not have justified automation.

But as e-commerce continues to surge, the case for automation is now too compelling to ignore.