4 Reasons To Choose Automated Parcel Sortation

By Scaletronic | 28/02/2022 | Share:

Taking use of automation for parcel sorting is useful for both shippers, and consumers so here are 4 reasons to choose automated parcel sortation.

The fast rise in E-commerce has been largely embraced by consumers – which can be a turned to a benefit for retailers.

With booming ecommerce trends, parcel delivery companies nowadays are facing difficulties when it comes to speed and delivery performance. Customers are constantly expecting shipments to be delivered faster than ever before.

To deal with this issue, many shippers have turned to a traditional solution- simply employing more staff for parcel sorting – which may not be a viable long-term solution. Automation offers a better way forward.

Why you need to consider automation

- Accurate Results

Mistakes can easily happen during a manual-sorting process. Mis-sorts and incorrect labelling can occur, which will affect the packages delivery time and ultimately result in customer dissatisfaction. Making use of automated parcel sorting guarantees constant accurate results. - Traceability or Data Tracking

There will be a decrease in requests about missing packages- customers are able to keep track of where exactly their packages are.

The data collected on a parcel within a specific time-frame can give an indication of operational efficiency and provide insights on how to improve the delivery process. - Improved Operations and Efficiency

Increasing numbers of parcels are handled in a shorter production window when using automation systems.

This solution can help with streamlining operations, i.e. tracking returns and inbound shipment. With the ability to see where packages are real-time, shippers can plan the staffing and equipment needed.

Enhanced efficiency rates can be generated from incorporating other business systems such as live invoicing systems and customs clearance systems. - Save Money

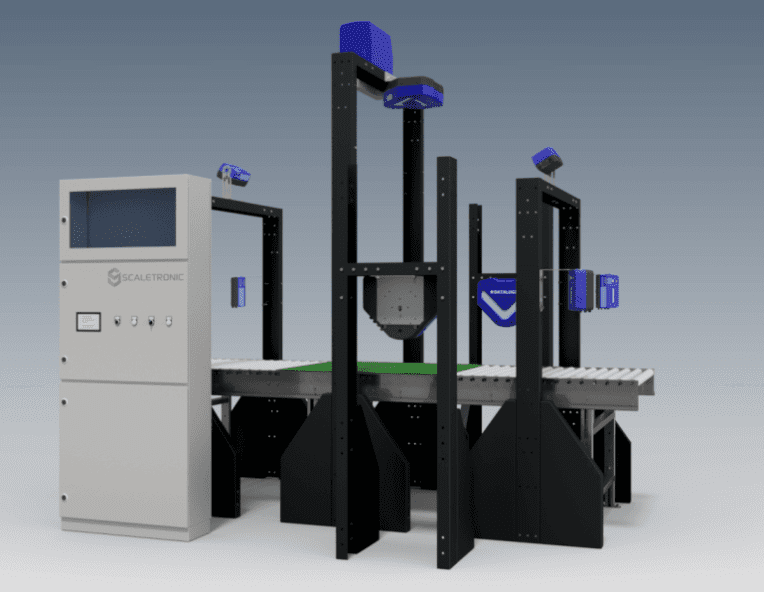

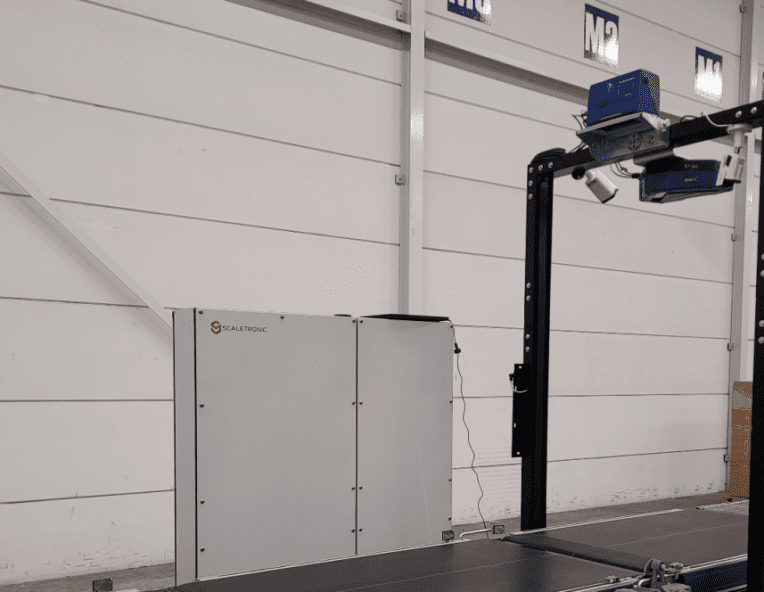

‘Time is money’ may be a phrase you’ve heard many times – well, it is indeed – now more than ever before. Utilizing automation will reduce costs through automating the tasks of scanning, weighing, dimensioning and sorting parcels. Automation should reduce the labour cost as well as your cost per parcel.

Embracing Automated Sortation

The above mentioned 4 reasons to choose automated parcel sortation are only the most common ones. Automating doesn’t mean replacing all existing systems. It could be a simple and strategical transition.

Logistics companies have begun to move away from the ‘hub-and-spoke model’ and a good place to start to automate is the parcel sortation at local and regional distribution centres.

In the past, the volumes at regional centres might not have justified automation, however with the increase of e-commerce it is becoming more realistic and a great place to start automating.

Learn more

Check out our guide to automated sortation equipment to understand the different parcel sortation technologies and the benefits to automated parcel sortation.