Why use Dynamic Dimensioning, Weighing and Scanning systems?

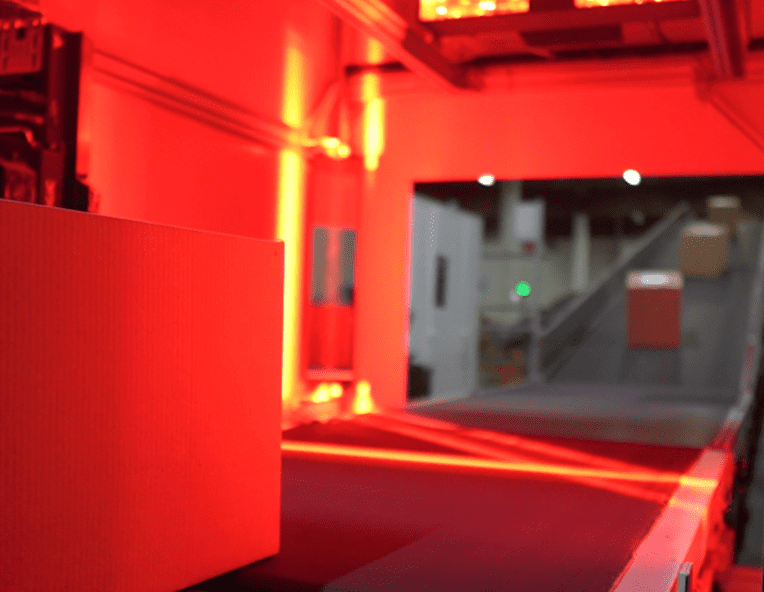

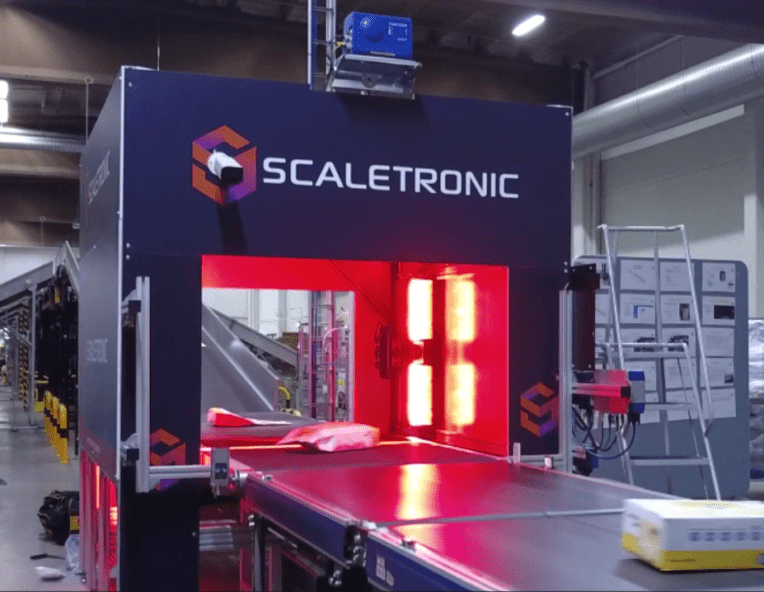

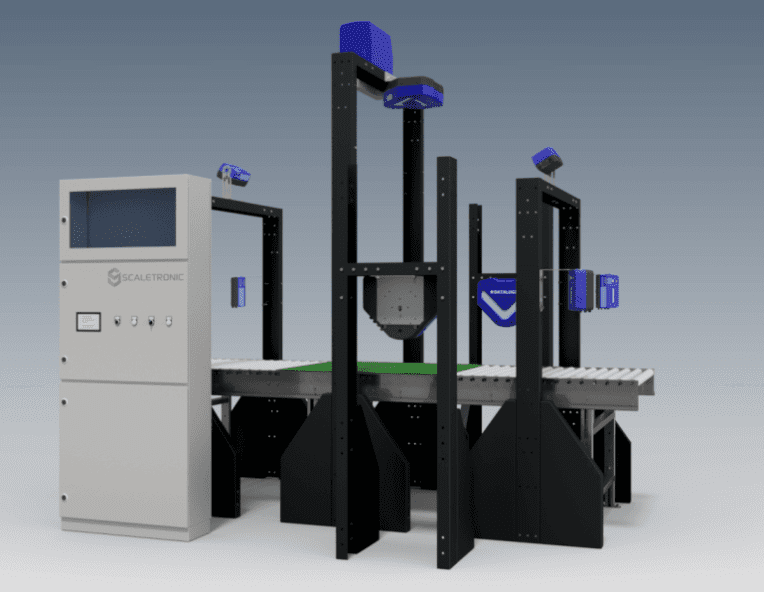

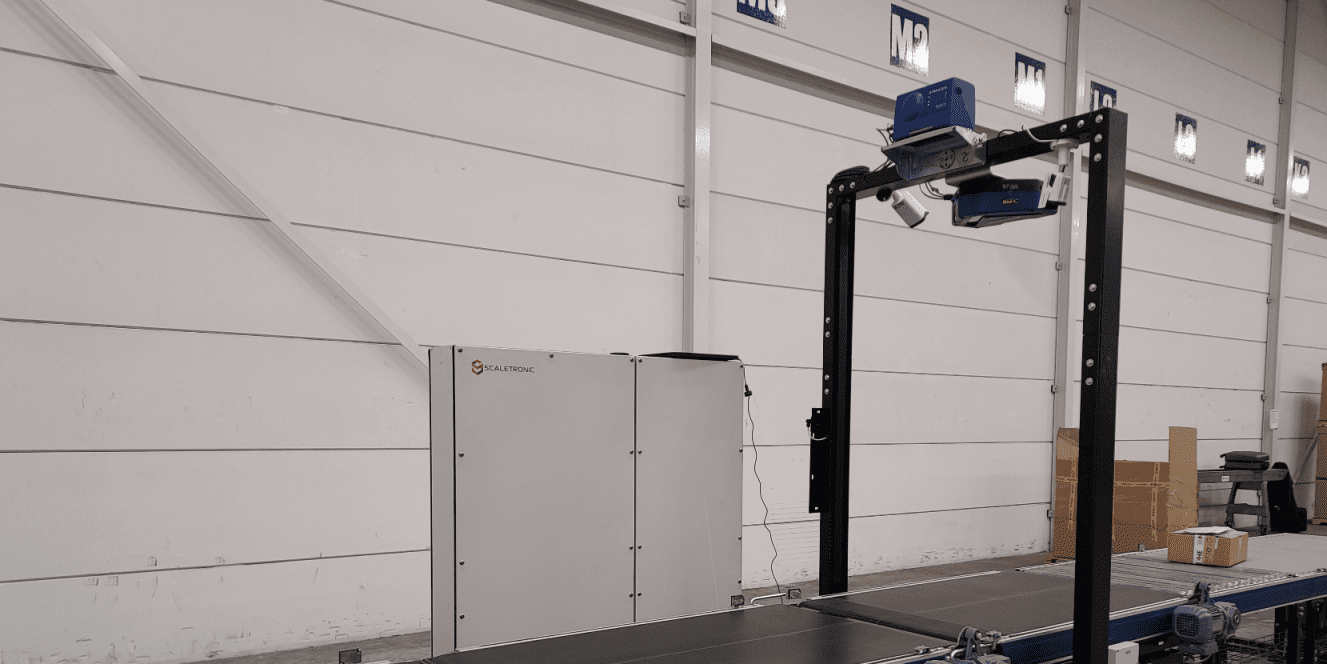

Dynamic DWS (Dimensioning, Weighing and Scanning) can improve parcel handling in logistics facilities, using intelligent data capture systems and automated sortation solutions.

By Scaletronic | 14/03/2022 | Share:

Dynamic DWS Dimensioning, Weighing, and Scanning

This automation technology solution enables Courier, Express, Parcel, Postal, and other logistics providers to acquire accurate package data in high-speed shipping, warehousing, and e-commerce applications.

Accurate parcel dimensions, weights and barcode ID are acquired as packages move at high speed, maximising operational efficiency, while increasing invoicing accuracy.

The bottom line for logistics providers is that efficient dynamic dimensioning and weighing systems increase their profitability, while enabling them to increase shipping accuracy, and deliver top-class customer service.

Before the explosion of online shopping, i.e., e-commerce, the courier, express and parcel industry mostly concerned itself with traditional B2B companies. These companies generally had defined package sizes and weights with simple, low volume, non-palletised small package shipping requirements.

When B2C e-commerce companies started selling and delivering anything, to anyone, located anywhere in the world the logistics industry’s shipping requirements became far more complex.

Why use Dynamic DWS?

For the e-commerce industry to survive and thrive, the delivery companies have had to implement new parcel weighing, dimensioning and package handling technologies to manage an exponential increase in the complexity of small parcel and poly bags volumes. Implementing new dynamic weighing systems enable CEP providers to handle both the volume, accuracy, shipping speeds, and package size diversity now common in the e-commerce and shipping logistics industries.

DWS systems provide significant cost benefits to CEP (Courier, Express, Parcel) providers.

DWS – Dimensioning Weighing and Scanning systems scan individual shipment labels while capturing accurate package weight and dimension information.

In a DWS application, it is all about accurately capturing the correct package dimensions and weight and connecting that weight to the correct item ID in order to accurately invoice the customer for the package delivery service.

Correctly connecting a specific package’s barcode ID to accurate package data provides the logistics provider with several revenue recovery opportunities including:

- Reduction in billing errors

- More precise package weights provide more accurate transport fees

- The option to invoice on actual weight or volume weight – which ever is highest

- Specific package weights and label data connected together enhances tracking and overall quality of service

DWS in Intralogistics.

As in logistics, capturing shipment weight and dimension information quickly and accurately is critical in intralogistics. Catchweighers or Checkweighers, i.e. dynamic weighing scale, and dimensioning systems capture package weight and size information dynamically as the packages are received and this information is merged with the package ID using barcode scanners or imagers.

This combined package information is used by the control system to either store the package in an optimum location for later use and shipment, or to immediately sort the package using automated sortation technology.

Dynamic weighing and dimensioning systems provide the accurate weight and item dimensions needed by any intralogistics system to maximize efficiency and thereby profitability.