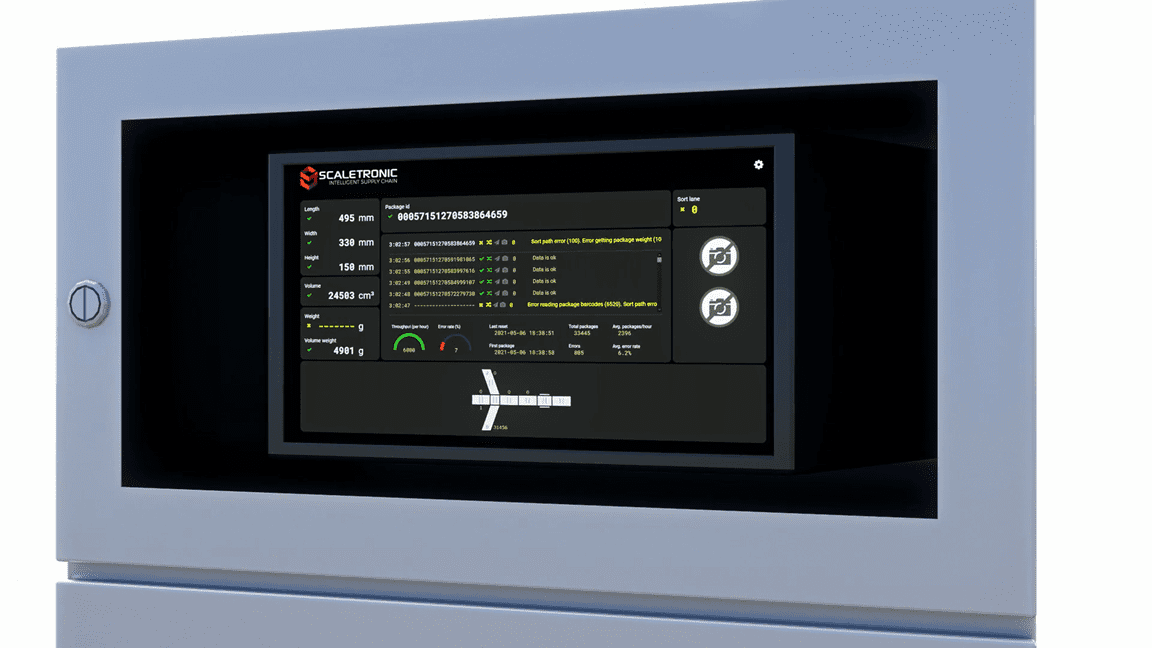

With throughputs of up-to 5000 parcels per hour, our parcel DWS stations ensure that you have accurate data on every parcel that you handle.

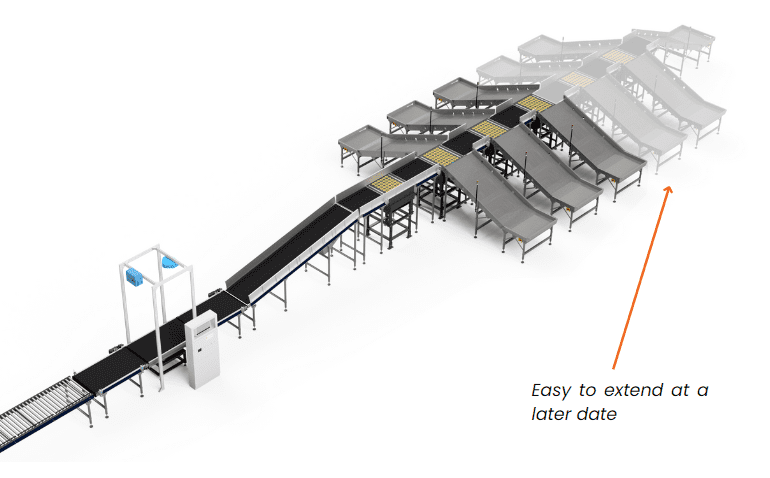

Automated parcel sorting can save a huge amount of resources and recover lost revenue.

Our automated sortation systems are modular, simple, and robust, improving productivity, accuracy, and efficiency in parcel sortation facilities.

Our dynamic Dimension Scanner for palletized goods and large cargo can process up-to 400 pallets per hour! Perfect for revenue recovery in cross-dock operations.

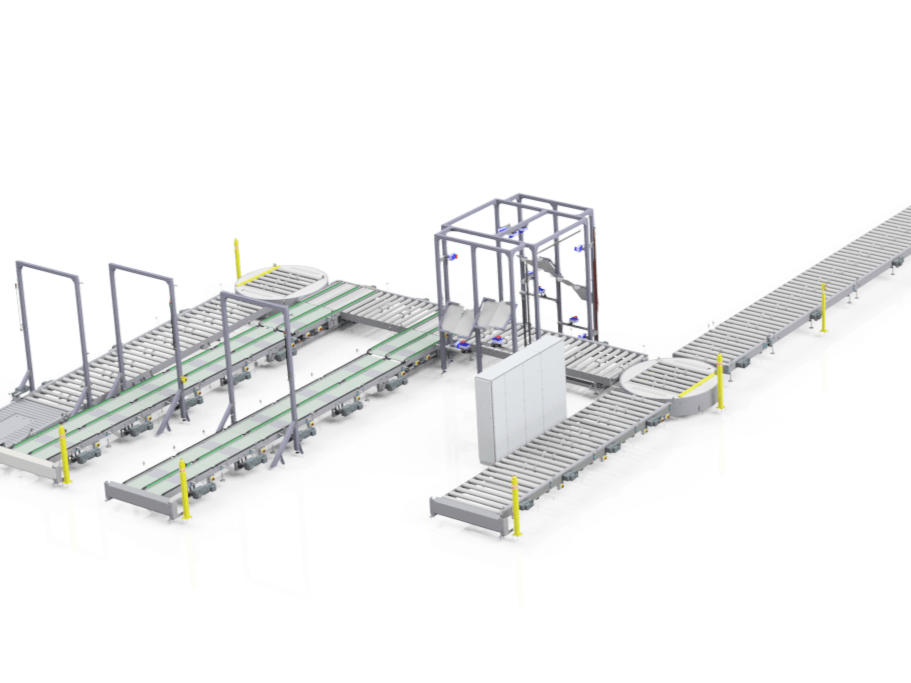

Discover Scaletronic's innovative Pallet Handling Automation solutions - featuring turntables, chain transfers, pallet lifts, roller & chain conveyors, and dynamic data capture (DWS). Enhance your logistics efficiency with our advanced, scalable systems designed for modern supply chain demands.

Semi-automatic volume and weight measurement of irregular shaped items that is ideal for inbound operations before moving items to stock.

OUR VISION

Our Vision is to become the go to provider of scalable parcel DWS & sortation solutions.

Are you curious about our process structure and how we manage your project?

Get acquainted with our 7 major processing steps that help us to remove the pain from your automation journey.

Our automation control software gives you great visibility of your data. With over 20 years of in-house experience, our software team has an extensive understanding of automation processes.

Modular and Scalable Automation

We've set out to redefine efficiency and flexibility in logistics with our state-of-the-art modular and scalable automation solutions. Tailored to meet the dynamic needs of modern supply chains, our systems are designed to grow with your business, ensuring that your investment adapts to changing demands.

Global Presence

We currently have representation in over 12 countries, offices in 3 countries and we’re continuously looking to expand.

Find My Local Office+45 Years Know-How

We set out in 1978, giving us 4 decades of experience and knowledge that we can share with you.

Learn More About UsRequest a Demo

Close