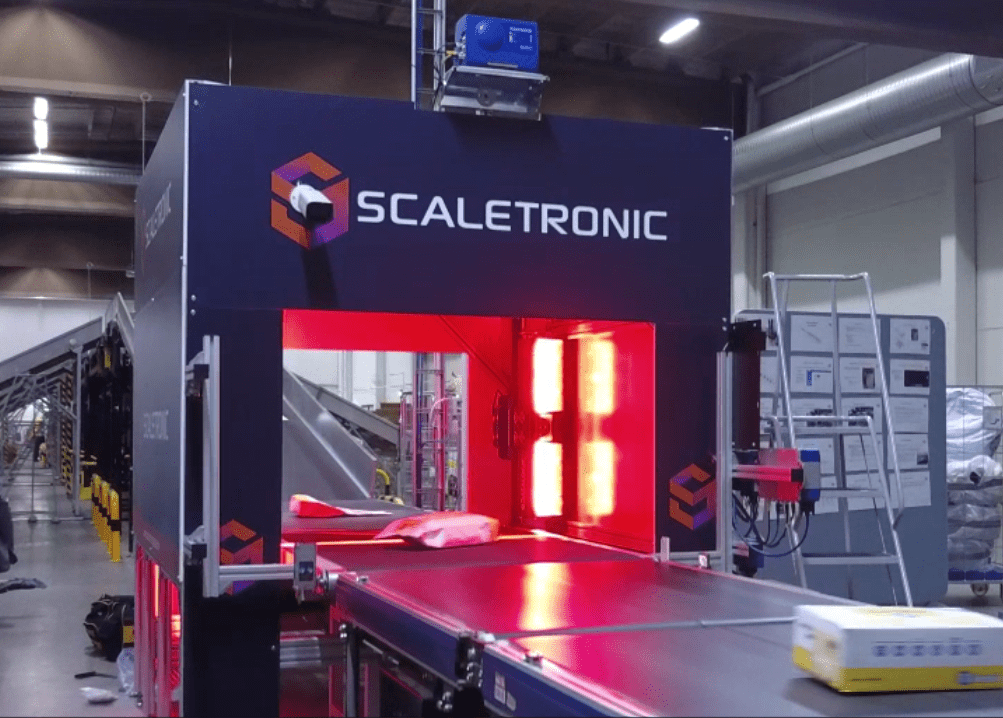

Parcel Data Capture

Smart Dynamic Data Capture

Dynamic DWS systems provide significant savings to Courier, Express, Parcel and Ecommerce logistics providers. Improve your revenue recovery with accurate data.

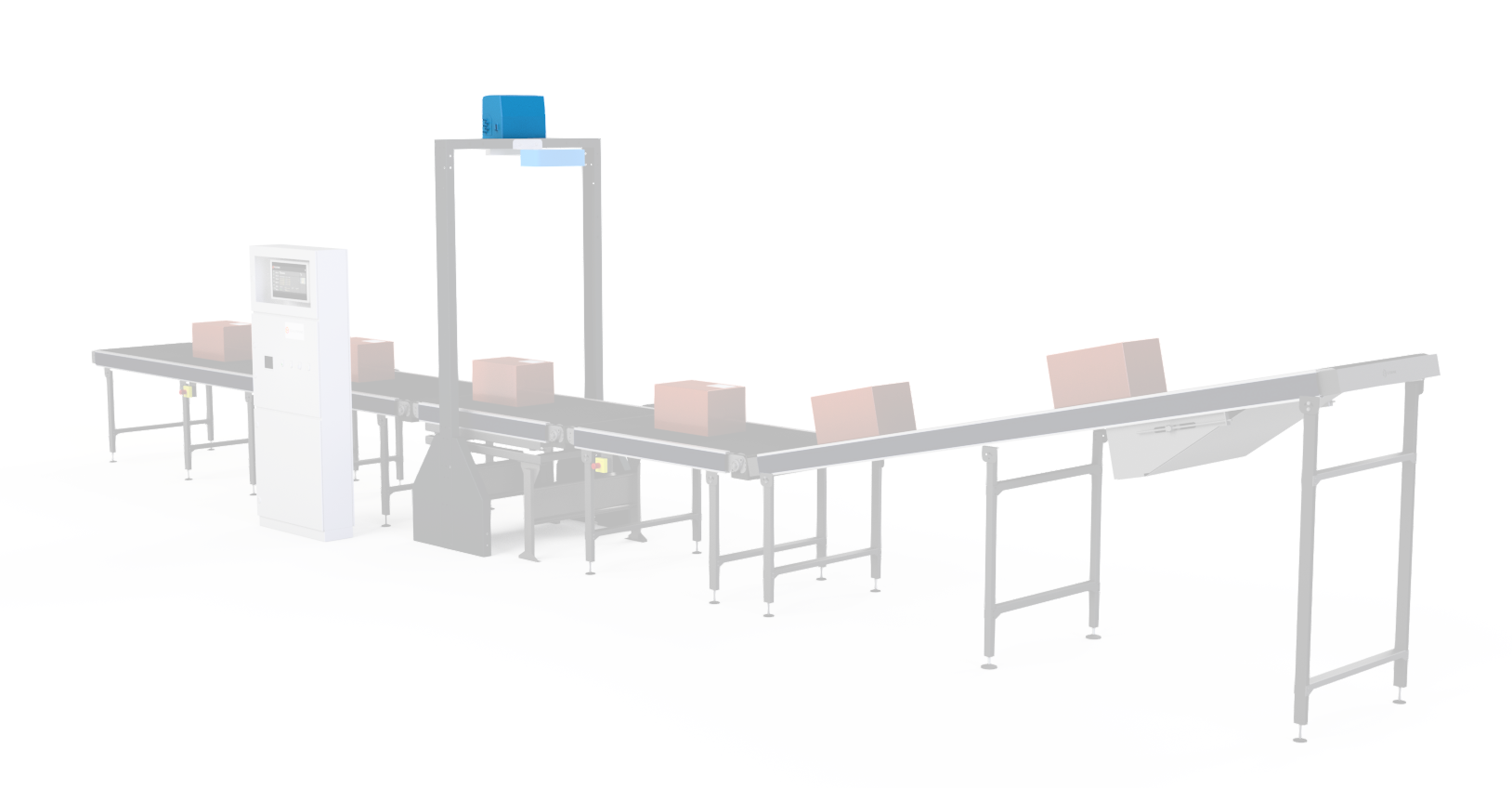

Dimension Scanner

Automatic Dimensioning System capturing the length, width, and height of the parcels.

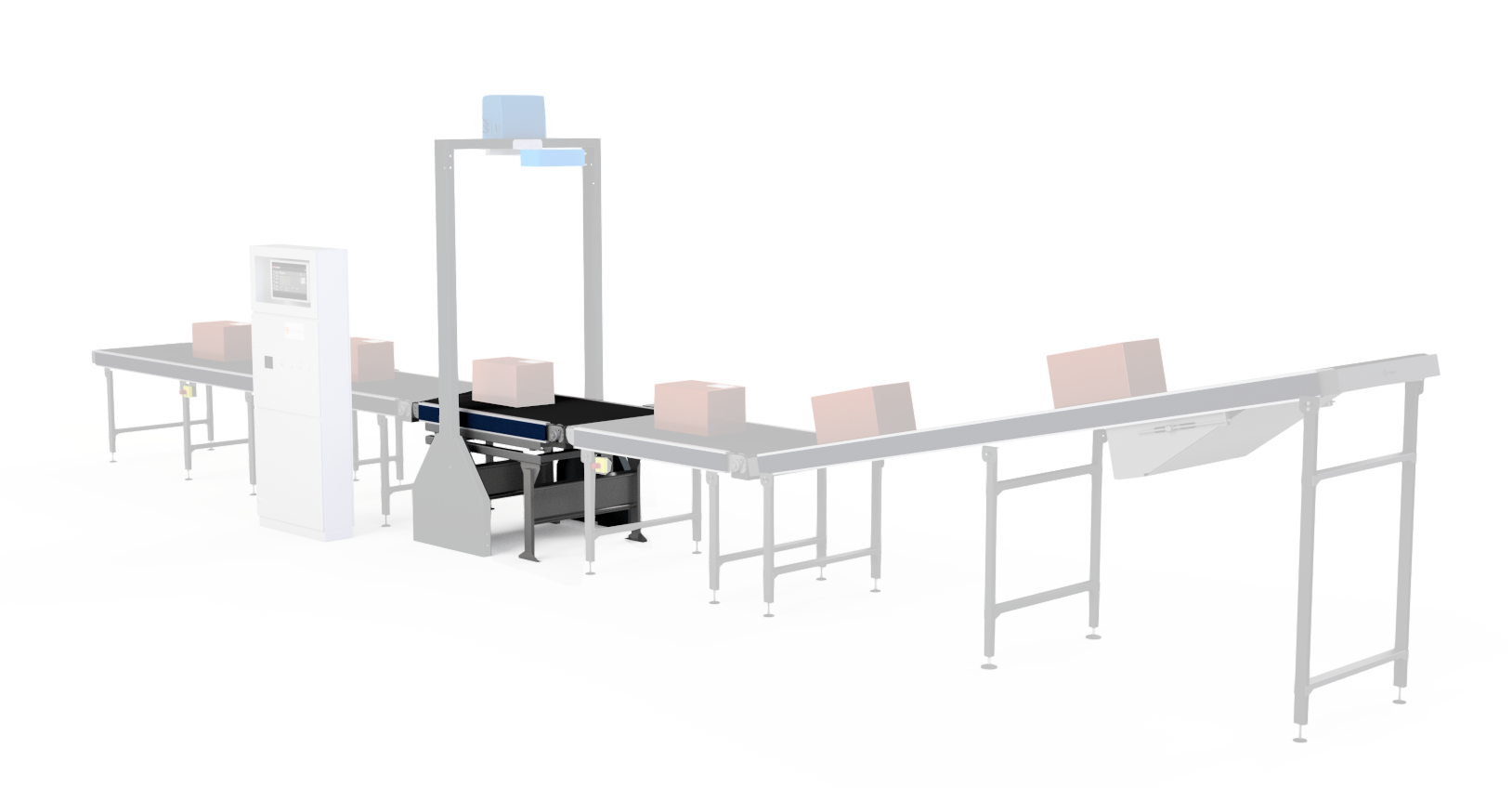

Weighing Scale

As parcels pass through the scanning station they are also weighed.

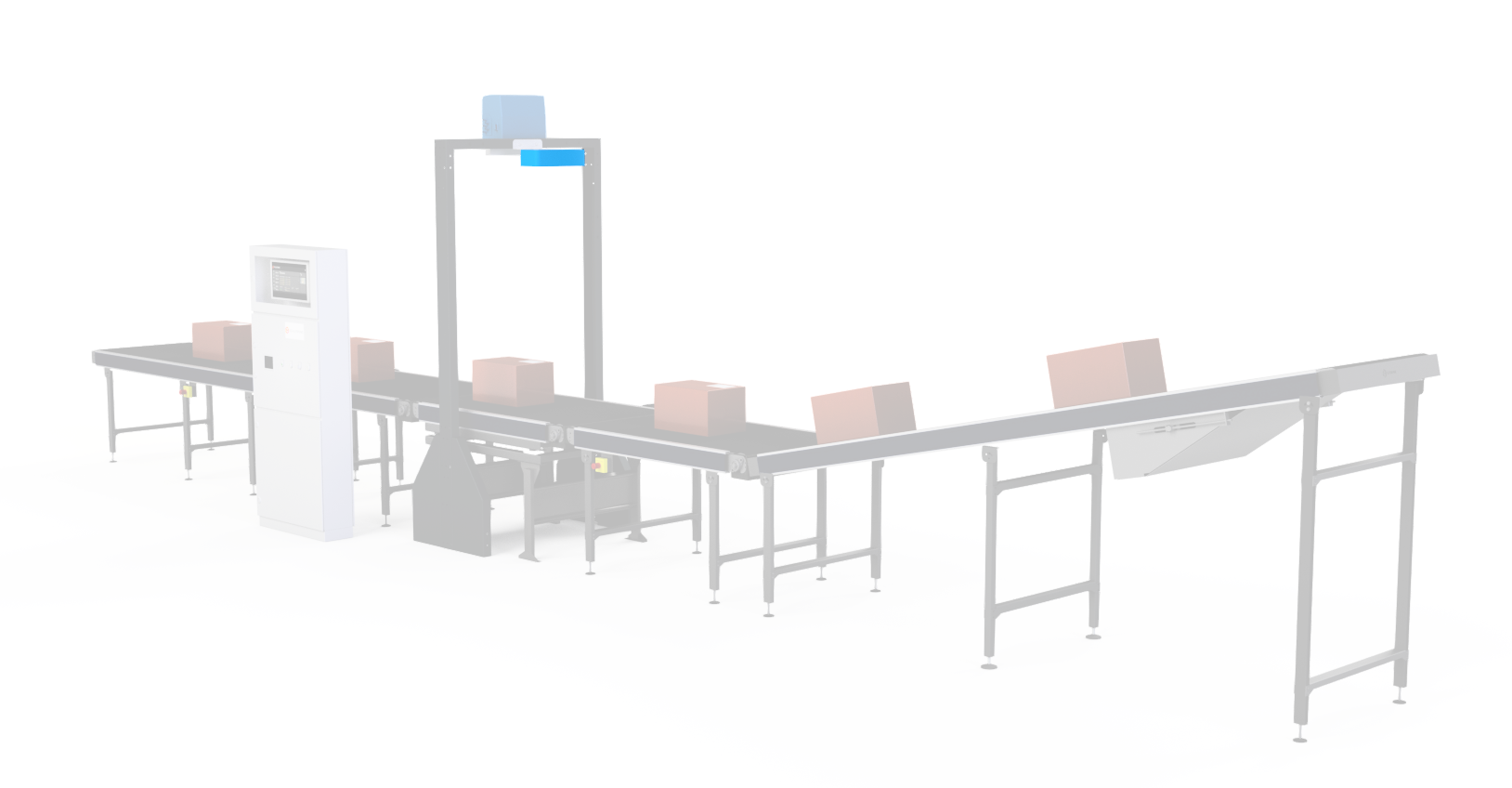

Multi-sided barcode reading

Automatic barcode reading on up to 5 sides of the parcels; Top, both sides, front and back.

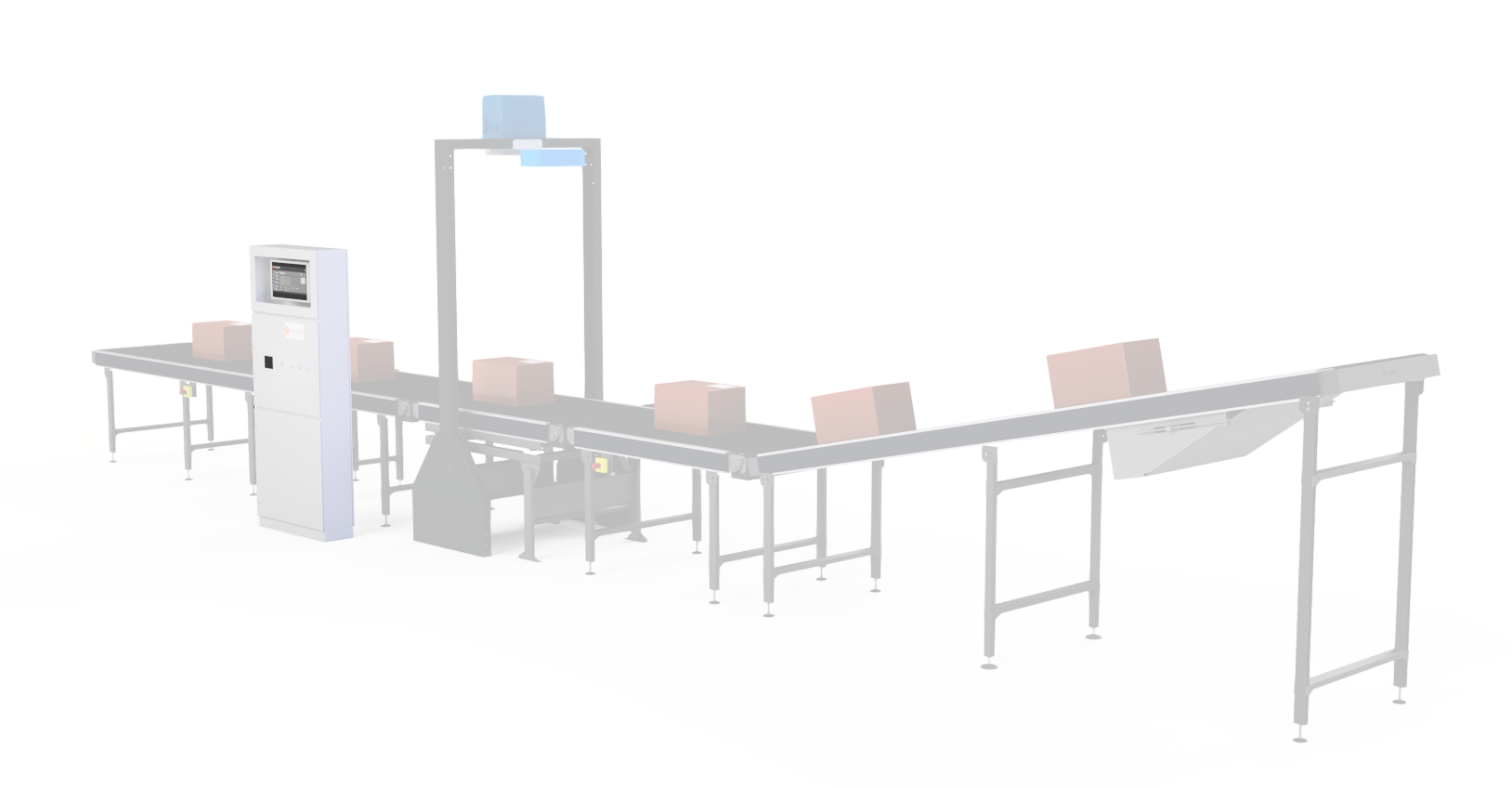

Touchscreen Control Panel

The whole system is operated from this control panel.

Certified DWS Systems

Accurate parcel dimensions, weights and barcode ID data are gathered, as the packages move at high speed through the scanning station, maximizing operational efficiency.

By accurately capturing dimensional and weight data in real-time, DWS technology enables improved invoicing, reduction in errors, and more profit per parcel.

Our Parcel Data Capture, DWS solutions are Legal-for-trade and MID approved.

Accurate Data

Automated data capture enables you to:

- Invoice correctly

- Reduce errors

- Reduce manual labour

The Scaletronic powerful data management software merges dimensions, weight and barcode data and stores it in legal-for-trade alibi storage.

Data is then sent seamlessly to your ERP or WMS system - and can be used further for communication with the sorter, updating invoices and generating management statistics.

Key Benefits

Accurate Data Capture

MID Approved

Scalable

Seamless Sortation

Scaletronic DWS systems seamlessly integrate with our sortation solutions. Our control software is the same for all our hardware.

The parcel data is captured, communicated to your ERP, and a sort destination returned.

The combination of Dynamic Dimensioning, Weighing, and Scanning (DWS) with automated sortation brings excellent benefits to logistics operations. By seamlessly integrating these technologies, businesses can achieve precise sorting and routing of parcels based on their dimensions, weight, and destination, leading to increased accuracy, accelerated throughput, and streamlined operations.

Control Software

Each of our DWS stations come with a touchscreen control panel. The DWS dashboard displays the data captured on each parcel, as well as key operational statistics such as hourly throughput, no-read rates and sort success rates.

However large or small your automation is, the complete system can be controlled and monitored from this single dashboard.

Request a Demo

Close