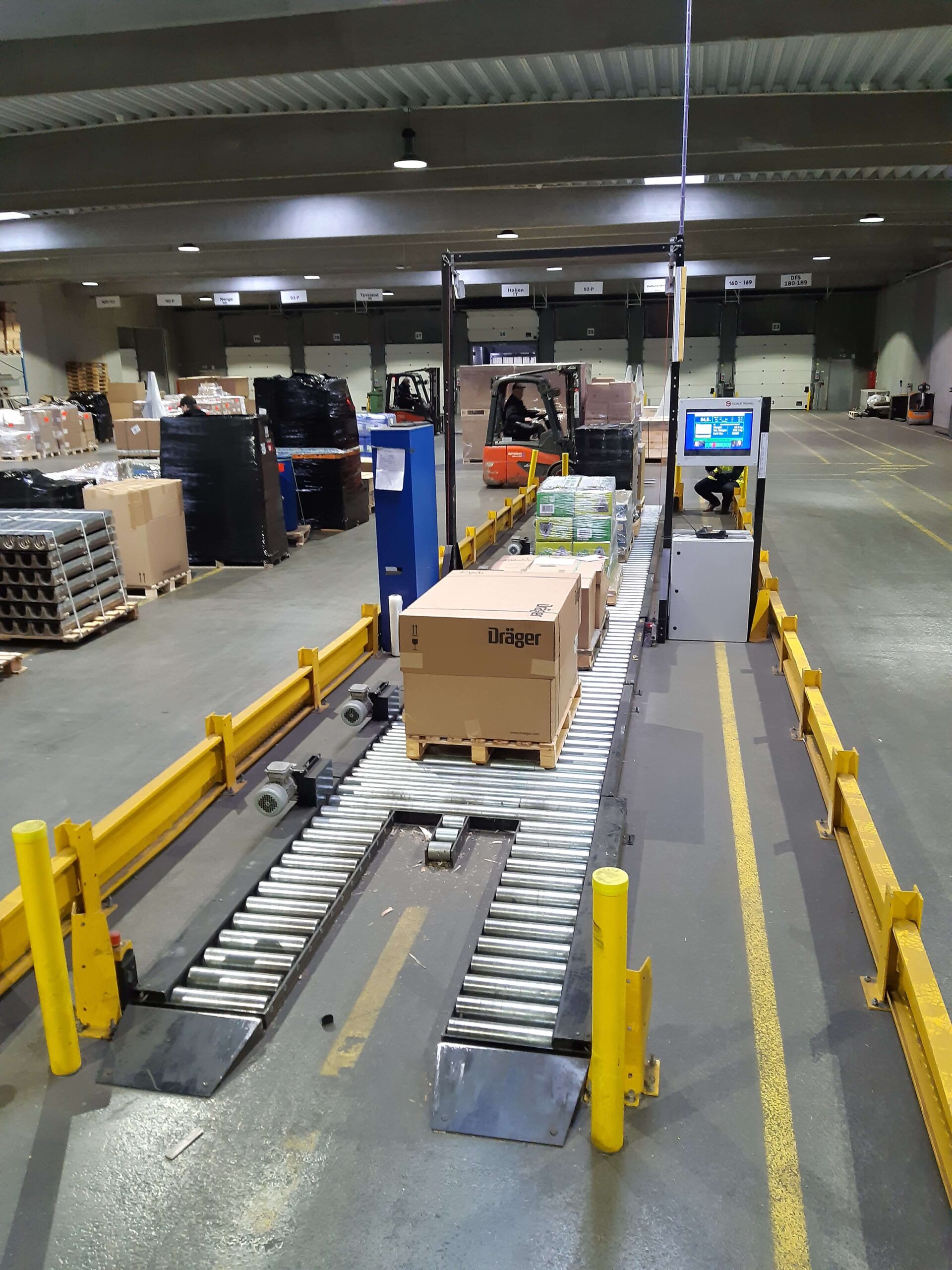

Pallet Data Capture

Automatic Pallet Dimensioning and Cubing

Our unique Scaletronic Dimension Scanner for pallets combines automatic Dimensioning, Weighing and Scanning features of palletized goods.

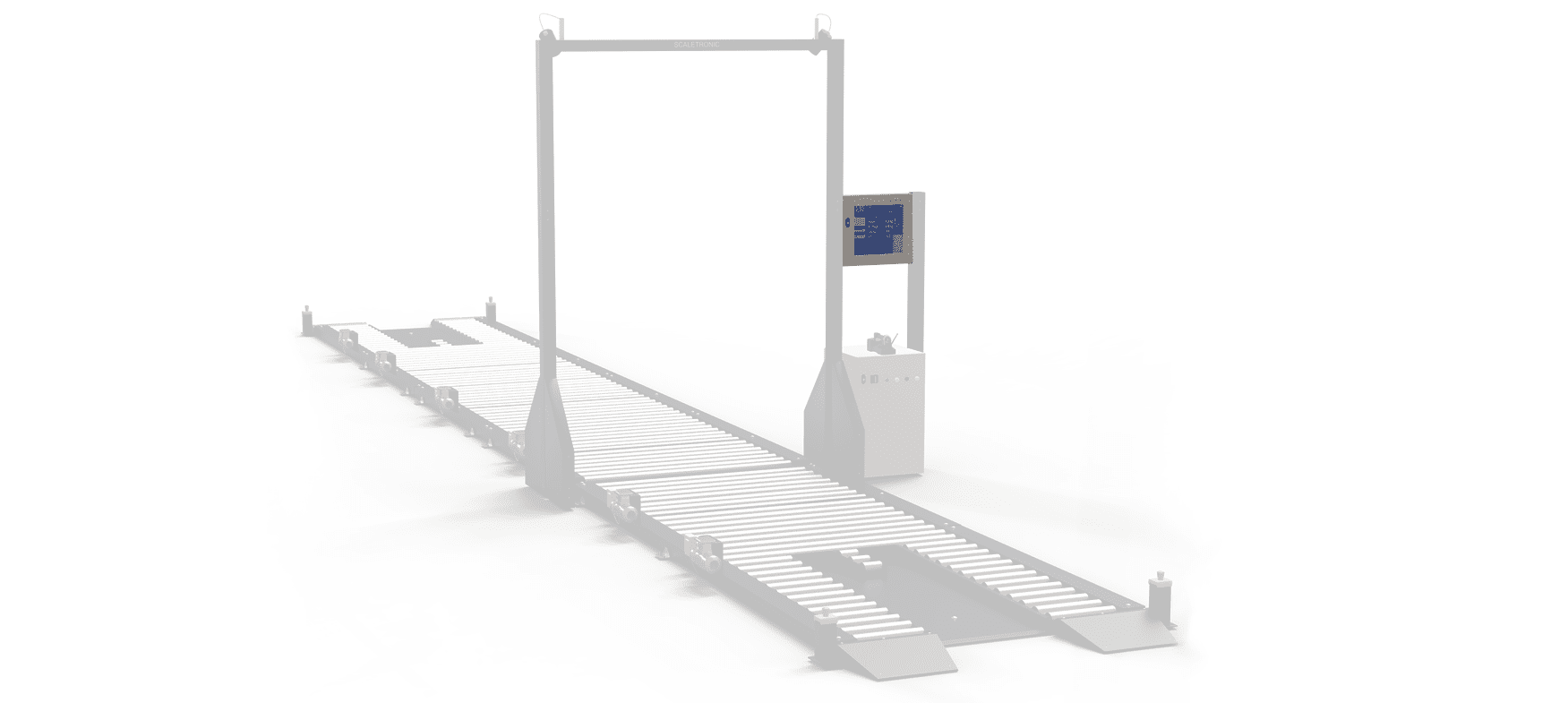

Touchscreen control

The whole system is operated from this touchscreen control panel.

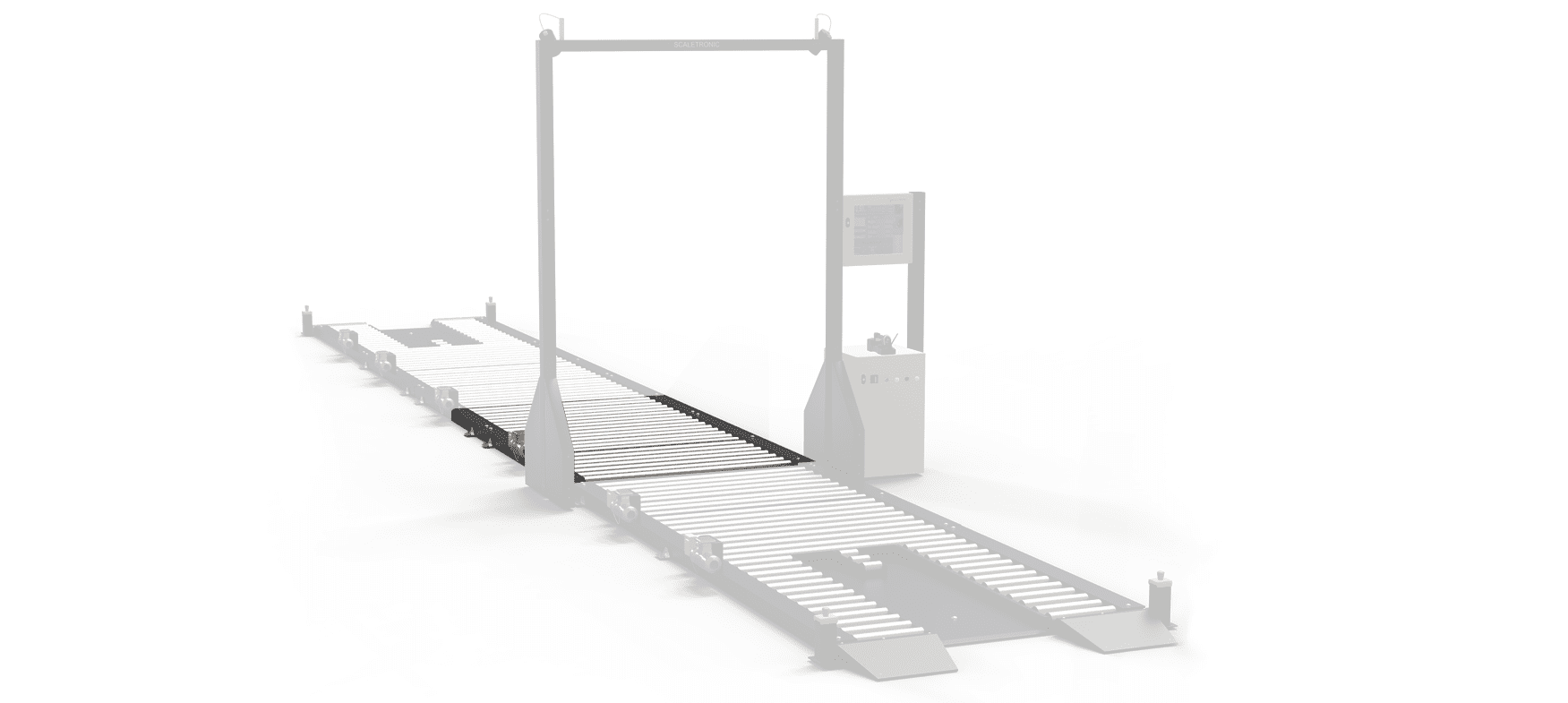

Weighing Scale

The weighing scale is built into the roller conveyors and accurately captures the weight of the pallet passing through the system.

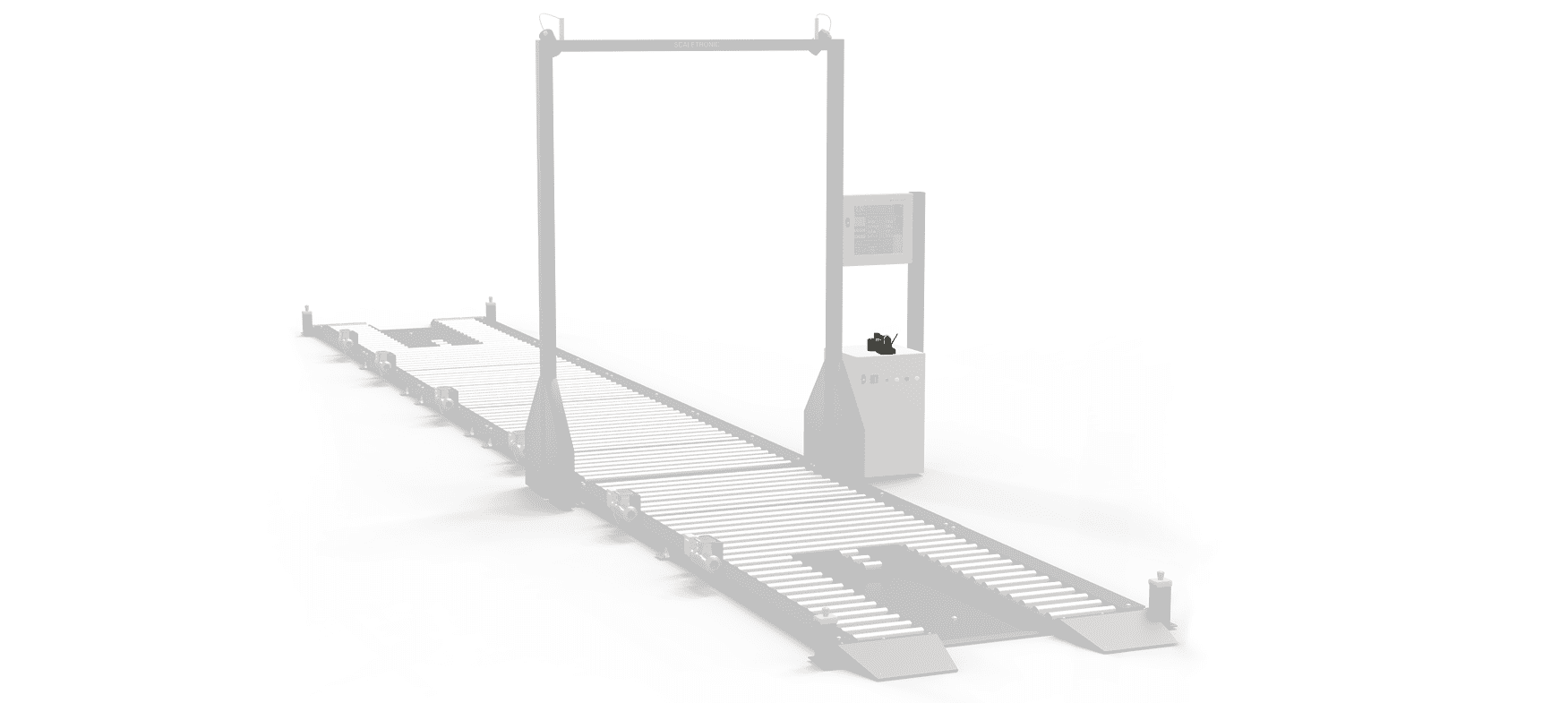

Scanning

Barcode reading - with a handheld barcode reader as standard, but can also be fully automated with imagers.

Dimensioning

The dimensioning system accurately captures the length, width and height of the pallet passing through the system.

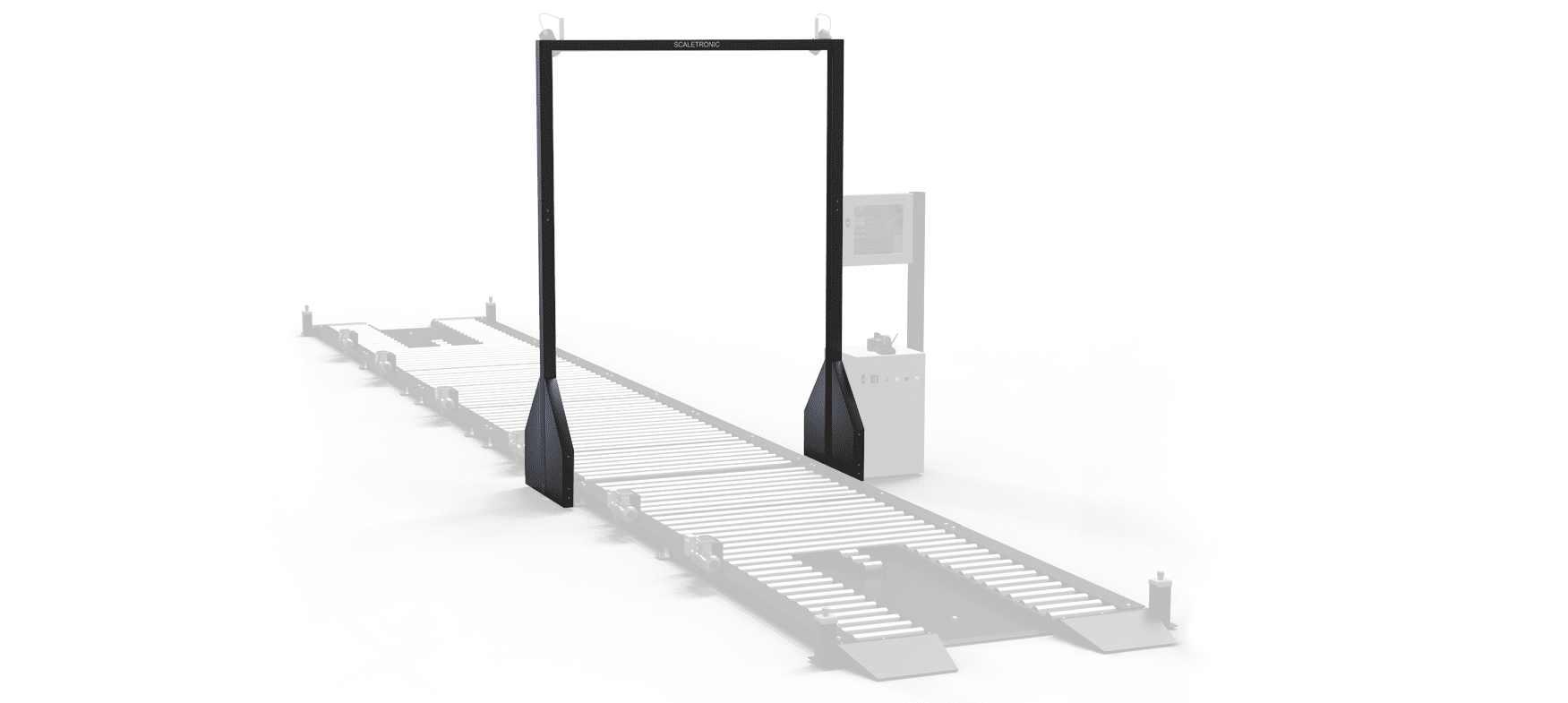

Pallet Dimension Scanner

This certified Pallet Dimension Scanner offers a reliable and efficient solution for accurately measuring the dimensions of palletized goods. With advanced scanning technology, it enables quick and precise dimension capture, allowing businesses to optimise space on trucks, improve inventory management, and invoice on volume as well as weight.

The semi-automatic feed system can be configured with different buffer capacity for pallets and can be customized in size to fit your requirement.

Data Communication

The Pallet Dimension Scanner from Scaletronic provides seamless data communication capabilities. It can easily integrate with client WMS or ERP systems via API or FTP, allowing for efficient exchange of dimensional data.

With support for HTTP, HTTPS, FTP, and SFTP protocols, our Pallet Dimension Scanner ensures smooth and secure data transmission, enabling you to enhance your logistics processes with accurate and timely information.

With real-time data in your WMS, TMS or ERP system you can invoice better, plan routes better and reduce distribution errors.

Key Benefits

MID Approved

High Volume Throughput

Automated Data Capture

Sturdy & Reliable Construction

The Pallet Dimension Scanner is built with a sturdy and reliable construction, ensuring its durability and long-lasting performance.

Made with high-quality materials and robust engineering, it is designed to withstand the demands of industrial environments and continuous usage. This ensures that you can rely on the Pallet Dimension Scanner for accurate measurements and consistent operation, even in challenging conditions.

With its sturdy and reliable construction, this pallet DWS provides peace of mind and a dependable solution for dimensioning palletised goods.

Accurate Invoicing

With the data provided by the Pallet Dimension Scanner, you gain the ability to invoice accurately based on precise dimensional measurements.

The scanner captures accurate dimensions of palletized goods, ensuring that invoicing is aligned with the actual space occupied by the shipments. This helps businesses avoid undercharging or overcharging their customers, leading to fair and accurate invoicing that improves transparency and customer satisfaction.

By leveraging the dimensional data from the scanner, clients can confidently generate invoices that reflect the precise dimensions of their shipments.

Request a Demo

Close