Automated Parcel Sortation

Automated Sorting Solutions

Increase throughput. Increase accuracy. Decrease overheads.

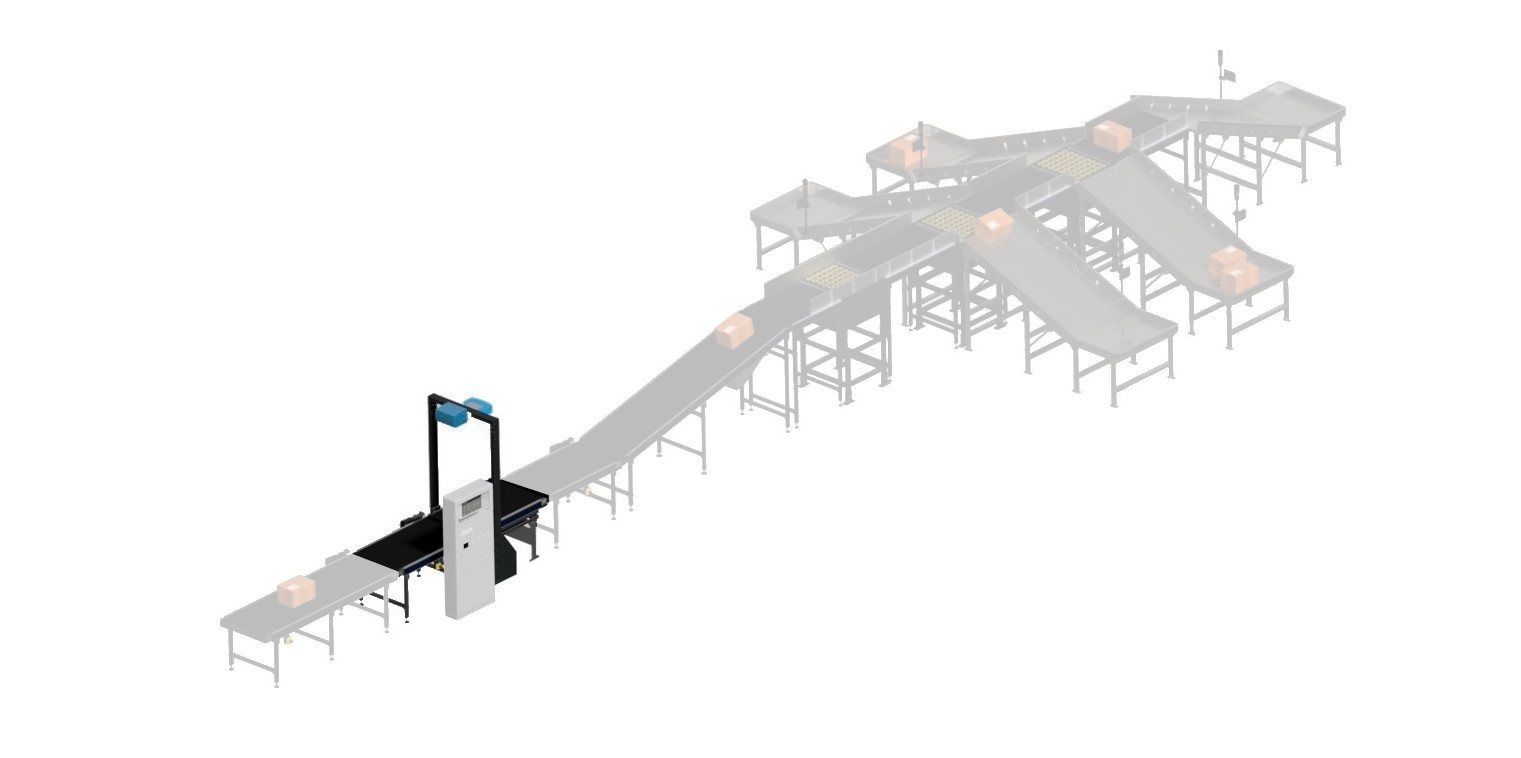

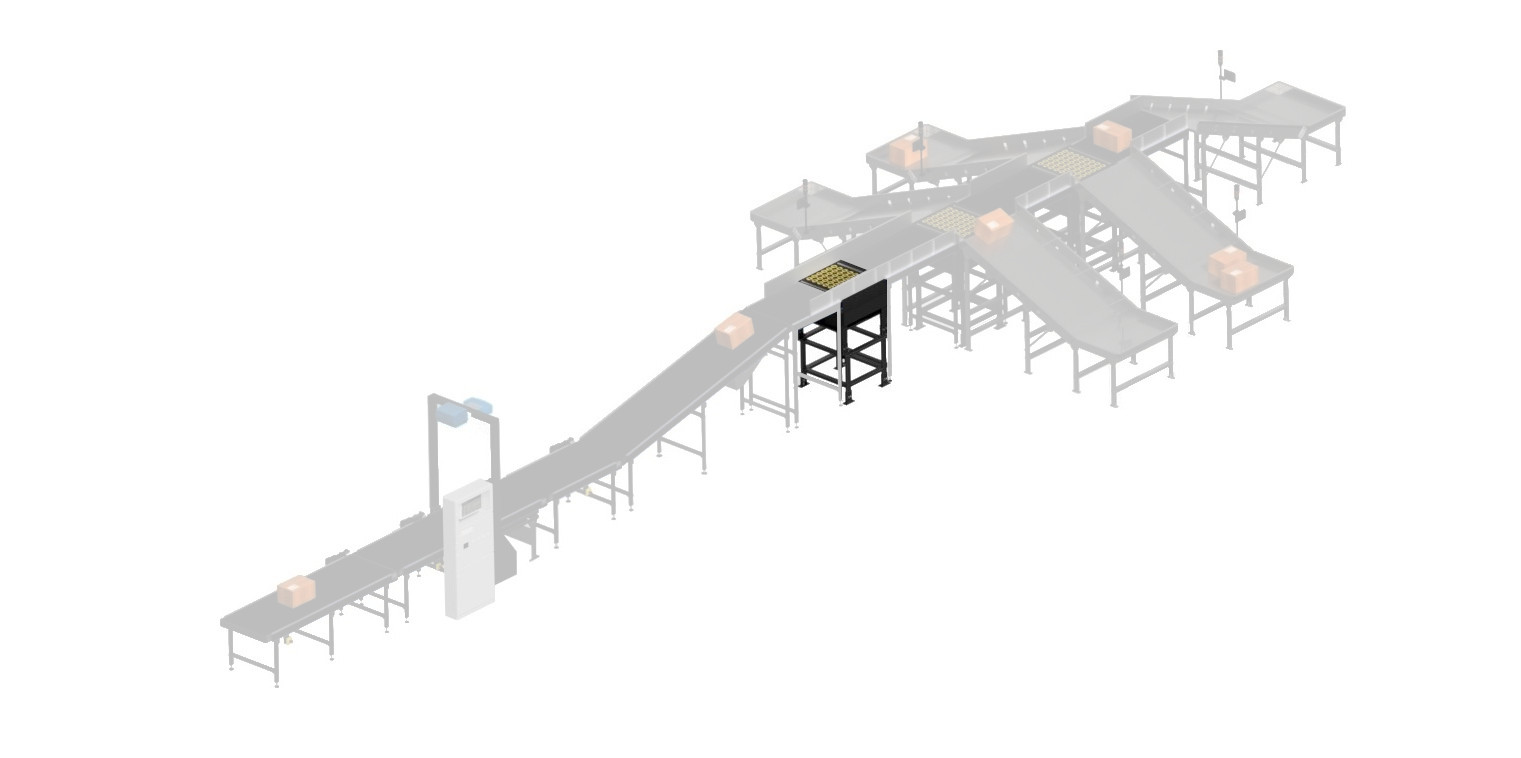

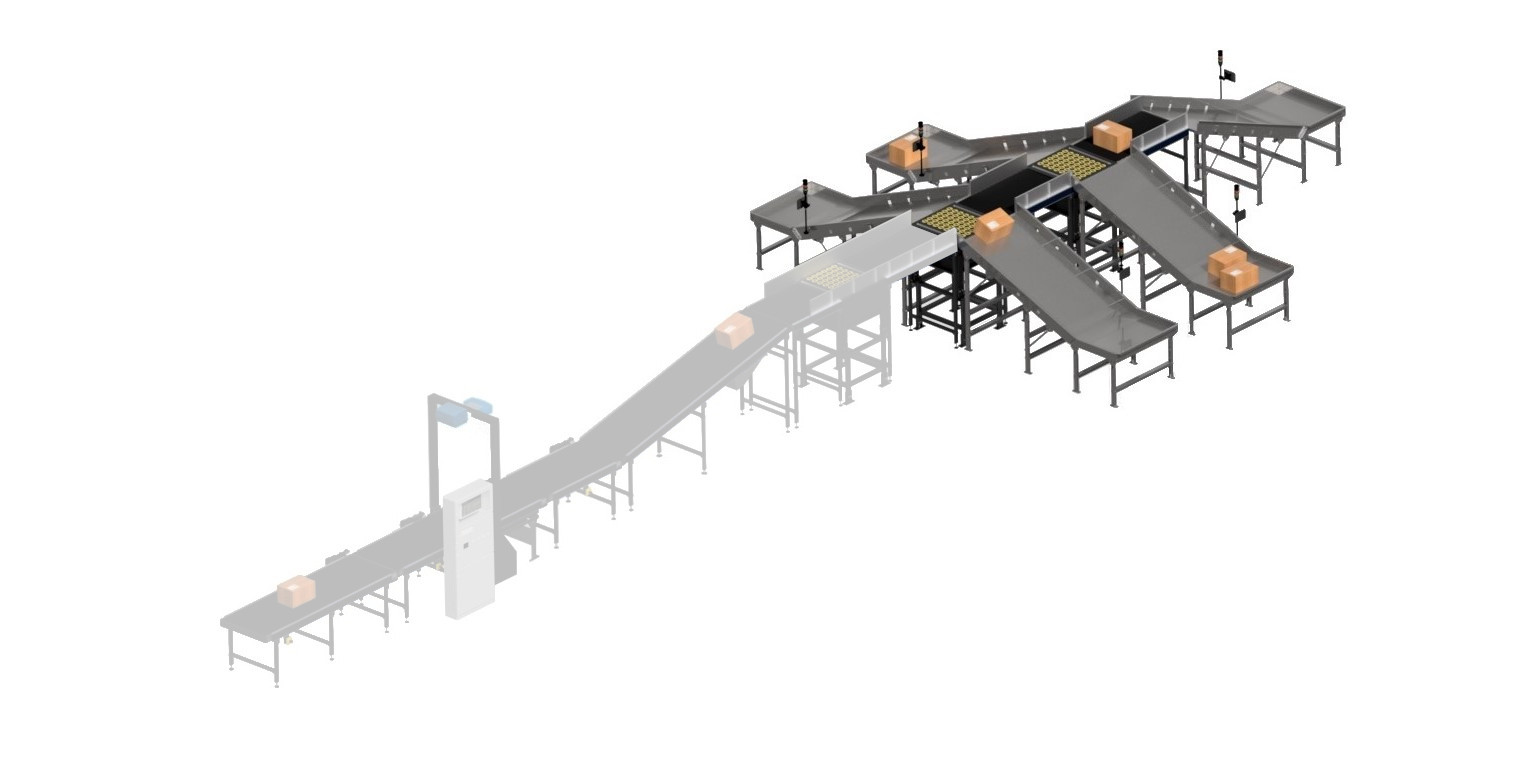

Data Capture

The barcode is scanned and communicated to the client for sort destination.

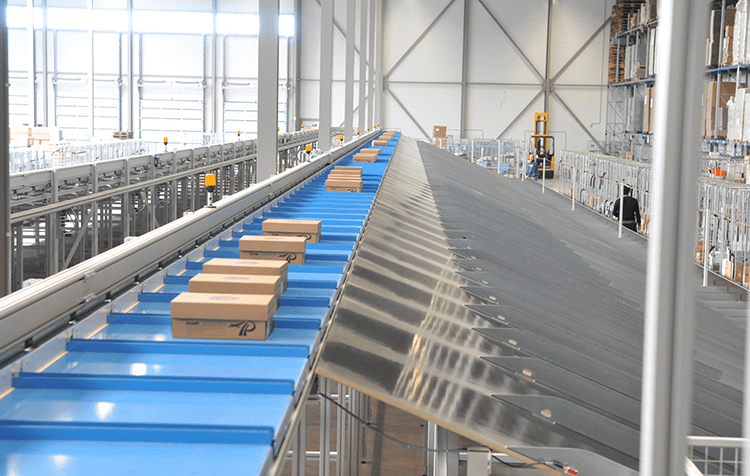

Pre-Sort

The parcel is aligned left or right on the sorter main line to prepare it for sortation to the correct chute.

Automated Sortation

Rugged polyurethane wheels handle a wide range of shipments with ease.

Chutes

The chutes are designed according to the application and freight profile. Can be metal slides or non-powered roller conveyors.

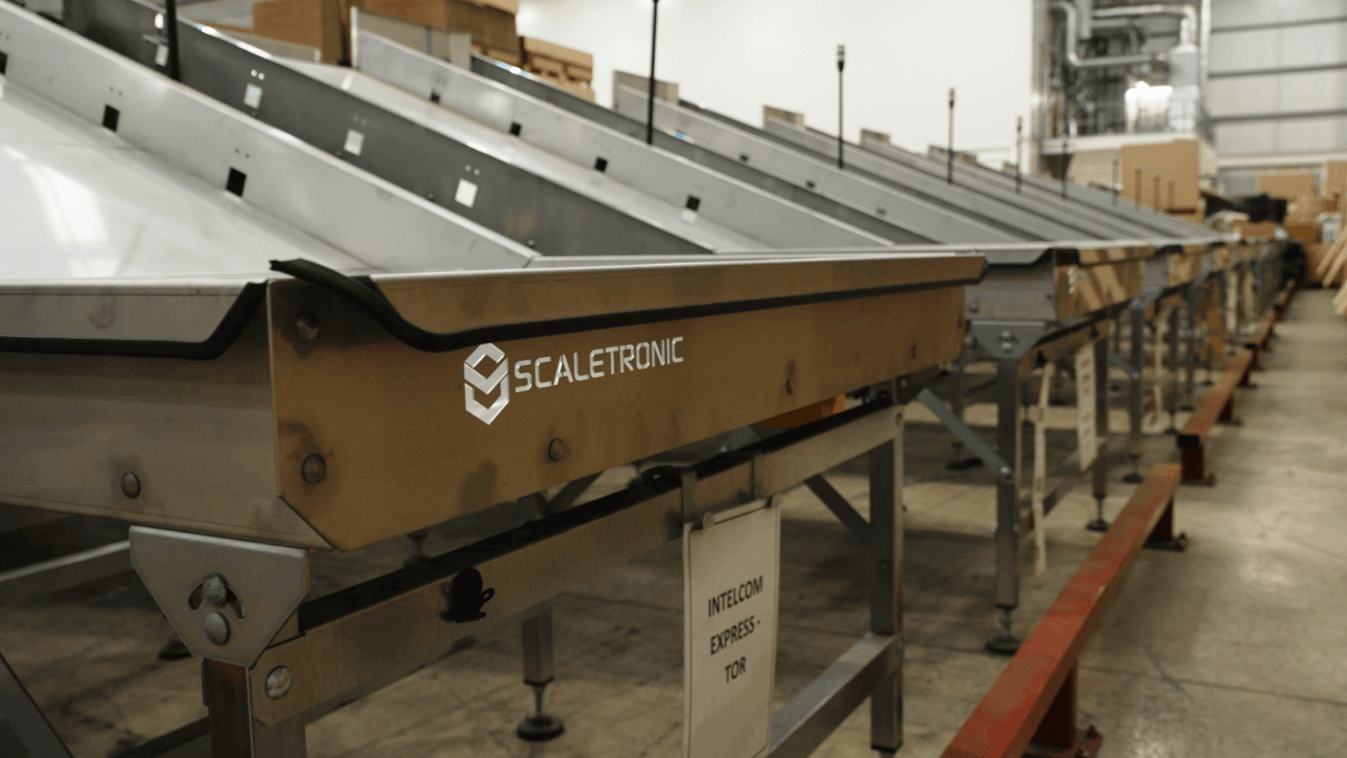

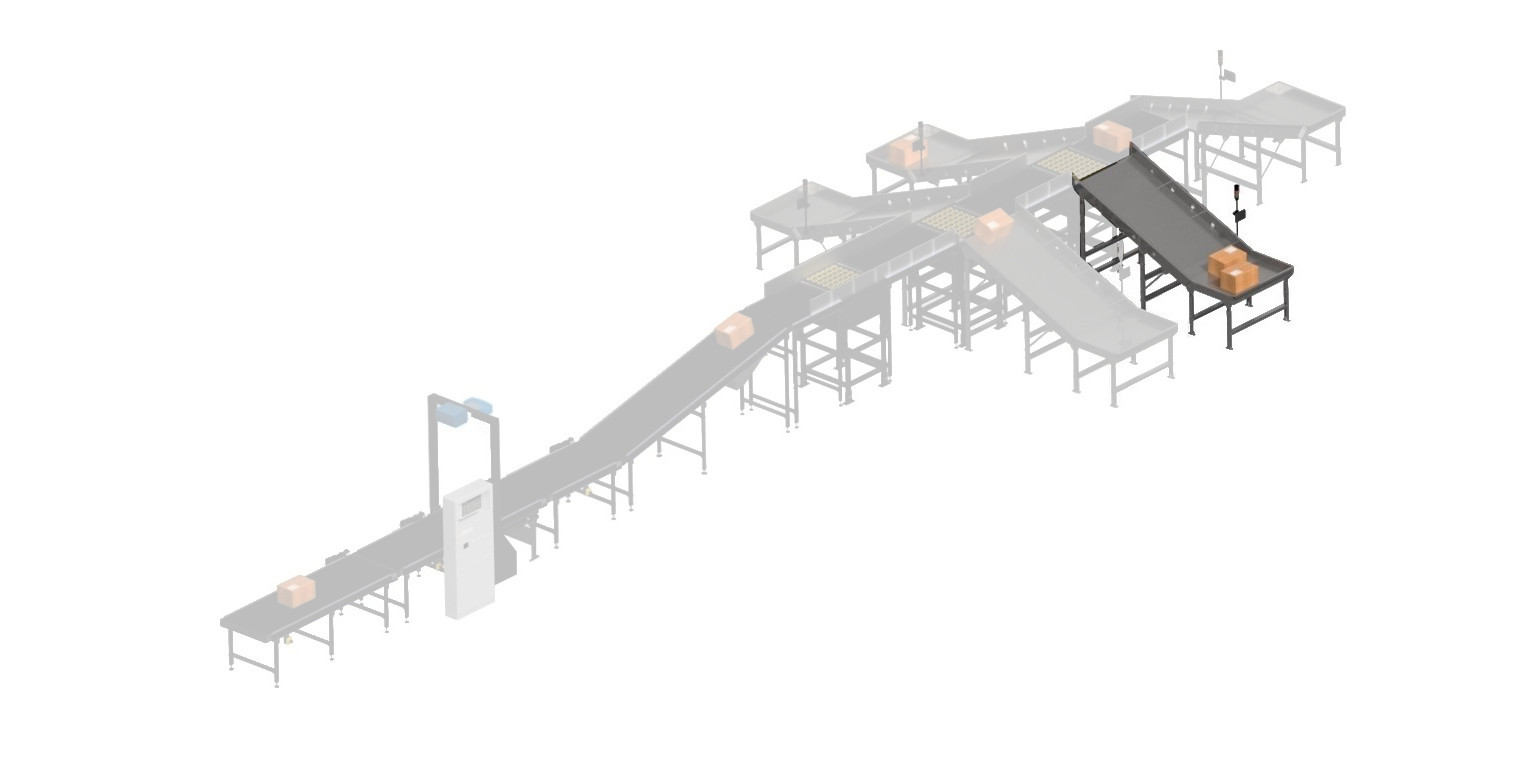

Wheel Sorter

The Wheel Sorter by Scaletronic is a highly versatile sortation technology.

The technology is modular and utilises pivoting wheels that can divert up to 90°. Large variations in size, weight and throughput are no problem for this high-speed parcel sortation solution. It can be set in linear or loop configurations.

Our Wheel Sorter can easily divert both parcels and plastic bags at high speeds.

Cross Belt Sorter

Our Cross Belt Sorter System is designed for efficient parcel sorting. It utilizes a network of small belts on individual carriers that move both horizontally and vertically. These carriers position parcels over designated chutes or conveyors, ensuring smooth sorting.

With a throughput capacity of up to 12,000 parcels per hour, it effectively manages diverse parcel sizes and shapes, reducing errors and improving order accuracy. This system simplifies high-volume sorting operations, offering enhanced efficiency and reliability for logistics centers.

Push Tray Sorter

The Push Tray Sorter is a dynamic and cost-effective solution for accurate parcel sorting. Engineered with precision, this high-speed, continuous-loop conveyor leverages a unique bar mechanism to gently push items off individual trays, accommodating a diverse range of shapes, sizes, and weights.

Pop-up Belt Diverters

Belt Diverters are typically 24V units and can sort parcels with a flat underside. The parcel is centered over the diverter belts and then the belts lift and transfer the parcel left or right and 90 degrees. The parcel handling is very gentle, making it well suited to fragile goods. Pop-up Belt Diverters are only configured in a linear design.

- Low volume throughput: 2,000 parcels an hour with 50kg capacity.

- Compact footprint: Get automated sortation without losing valuable floorspace.

Key Benefits

Large range of items handled

High Volume Throughput

Unlimited Sorter Lanes

Improved Operations and Efficiency

With sortation automation, an increasing number of parcels are handling in a shorter production window. Tools used to track returns or inbound shipments are often utilized – this can help with streamlining operations.

With the ability to see where packages are real-time, shippers can plan the staffing and equipment needed.

Better efficiency also can be achieved through incorporating other business systems, such as live invoicing systems or customs clearance systems.

Accurate Results

Mistakes are easily made during a manual-sorting process, mis-sorts and incorrect labelling will affect packages being delivered on time and can ultimately result in customer dissatisfaction.

Making use of automated parcel sorting guarantees constant accurate results.

Combining sortation automation with advanced technologies such as barcode scanning, dimensioning, and weight measurement, these systems ensure precise sorting and routing of parcels, minimizing errors and improving overall operational efficiency.

Save Money

‘Time is money’ may be a phrase you’ve heard many times – well, it is indeed – now more than ever before. Utilizing automation will reduce costs through automating the tasks of scanning, weighing, dimensioning and sorting parcels.

Parcel sortation automation should reduce the labour cost as well as your cost per parcel.

Request a Demo

Close